About

Foundry – Robotic Automation

Matrix integrates robotic metal finishing automation for iron, steel, and aluminum foundries that need consistent edge condition, controlled surface quality, and reliable operations in abrasive, harsh environments. We specialize in robotic grinding, deburring, and de-flashing systems engineered for high duty cycles, effective dust and debris management, and repeatable results across shifts. Where needed, we also deploy rugged machine tending and inspection solutions for post-cast trimming and machining operations to keep flow stable from finishing to shipment.

Types of Parts We Work With

Our finishing cells are designed around casting families with repeatable features and known finishing requirements, including:

- Engine blocks, housings, knuckles, brackets, pump and valve bodies

- Medium and large castings with repeatable parting lines, gates, and flash conditions

Applications

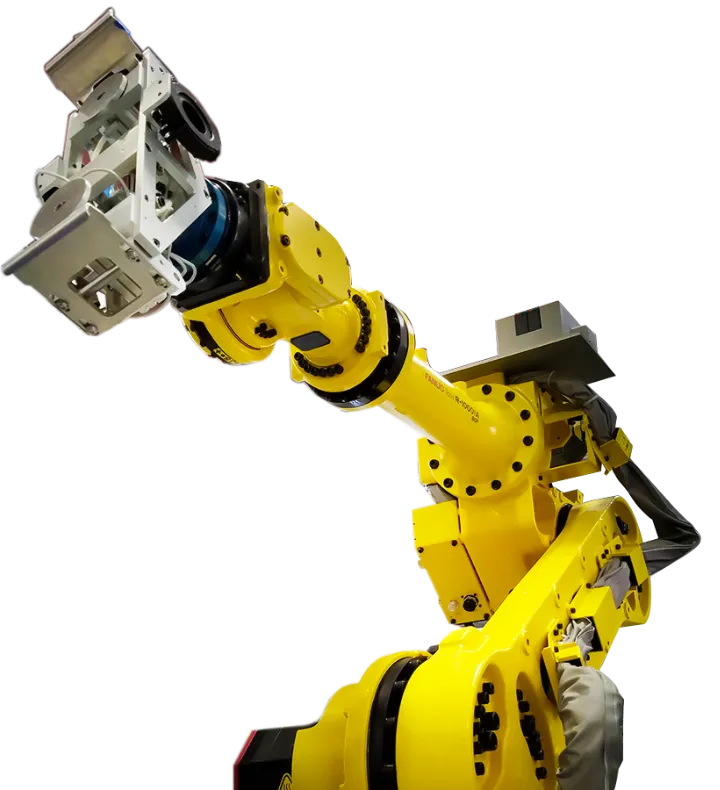

Robotic Metal Finishing (Deburring, Grinding, De-flashing)

Matrix delivers robotic finishing cells that remove gates and flash, grind parting lines, and produce consistent edge conditions without the variability or putting your operators in ergonomically challenging processes. Systems are engineered for the realities of foundry environments, including abrasive debris, heat, and heavy-duty cycle requirements. Typical capabilities include:

- Force-controlled compliance tooling for grinding gates, riser remnants, and parting lines with consistent contact

- De-risked finishing processes developed in the Matrix Deburr Lab to confirm abrasives, spindle selection, RPM, feed, force, and toolpath strategy

- Cell enclosures designed for dust control with integrated dust collection and spark containment appropriate for grinding operations

- Robust cell construction and guarding designed for high duty cycle operation and reduced downtime

- Strategies for tool wear management and process consistency, including parameter control to stabilize finish results across shifts

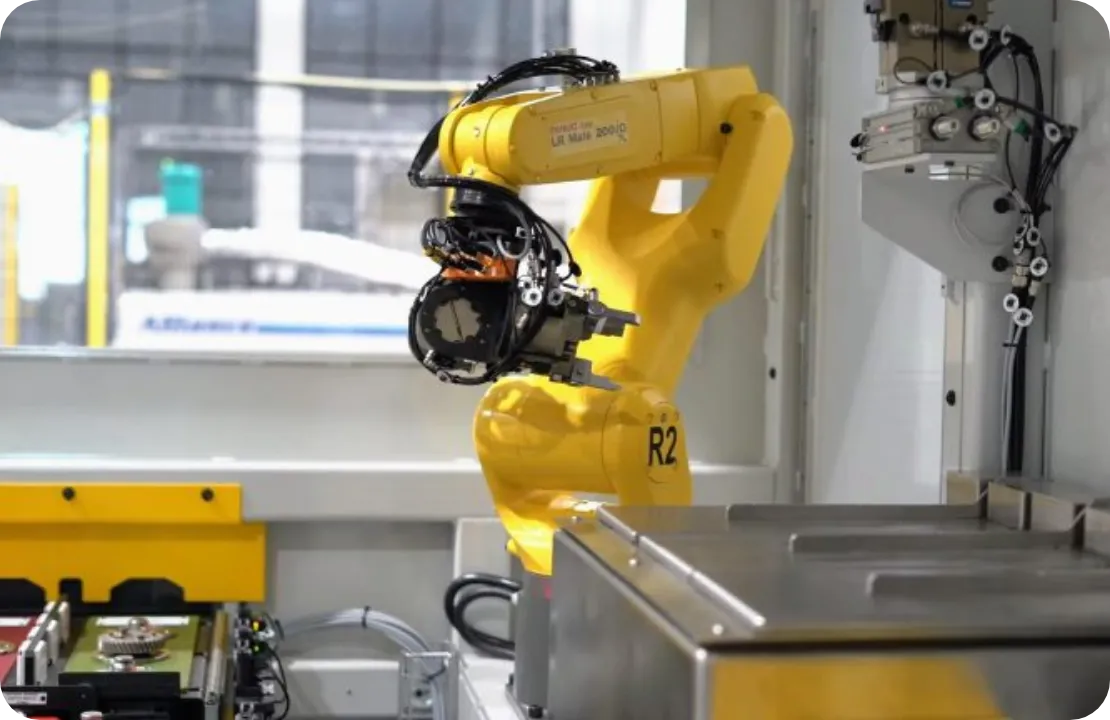

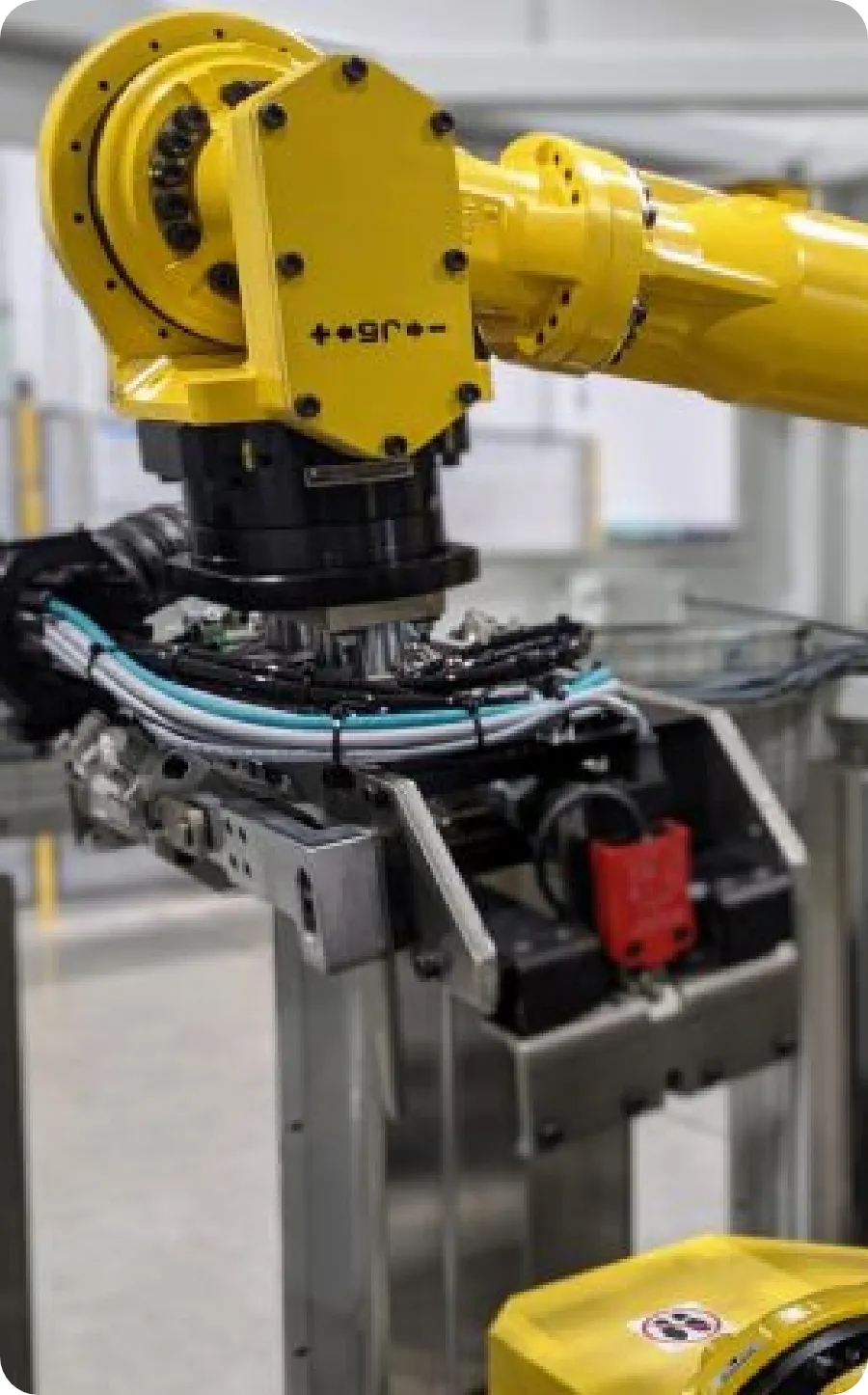

Robotic Machine Tending

For foundries that want to boost throughput after casting, Matrix integrates machine tending automation for trimming and machining steps that feed finishing and pack out. These systems are designed for rough surfaces, variable geometry, and heavy handling conditions. Common features include:

- Loading and unloading machining centers, saws, trimming stations, and downstream operations post-cast

- Rugged grippers and end-of-arm tooling designed for raw or rough-surfaced castings

- Custom fixtures and part presentation methods that ensure secure handling and repeatable orientation

End of Line Handling & Packaging

Where castings require controlled handling into shipping, Matrix provides end of line automation focused on protection and reliable transfers for heavy parts. Solutions often include:

- Robotic palletizing with protective dunnage to reduce damage during handling and shipment

- Conveyors and transfer systems engineered for heavy cast parts with uneven geometry and challenging centers of mass

Inspection & Traceability

To support quality assurance and process visibility, Matrix integrates inspection and plant connectivity options for finishing and downstream operations, including:

- Vision inspection for presence, position, and flash removal validation where applicable

- Plant system connectivity for process monitoring, production visibility, and reporting

Business Problems We Solve

Foundry finishing is frequently constrained by safety exposure, process variability, and the operational burden of managing abrasive processes.

Key challenges we address include:

- Safety and ergonomic risk from manual grinding, de-flashing, and heavy part handling

- Finish variation across shifts that drives rework, inconsistent downstream fit, and unpredictable quality

- Dust and debris containment challenges, including spark management and housekeeping burden

- Abrasive media usage and tool-life instability that increases consumable cost and reduces uptime

- Bottlenecks created by manual finishing capacity limits and inconsistent cycle times

Why Foundry Teams Choose Matrix

- Purpose-built finishing cells engineered for abrasive, hot, and dirty environments with high duty cycle requirements

- Proven process development approach that validates tooling, abrasives, and parameters before full-scale deployment

- Deep experience with grinding, deburring, and de-flashing across a wide range of part geometries

- Practical integration capability from trimming and machining through finishing, inspection, and shipment handling

Matrix’s foundry automation is designed to bring stability to the most variable and harsh finishing environments. By standardizing grinding and de-flashing processes with validated tooling and robust cell engineering, we help foundries reduce risk, improve consistency across shifts, and increase throughput while controlling dust, wear, and downtime.

Free Evaluation

Free Automation Evaluation Process

Have you ever thought about automating but weren’t sure where to start?

Contact us to go through our completely free Automation Evaluation Process.

By the end of this proven process, you will have a better understanding of how and where automation could fit into your current manufacturing operations.

Contact us to start your free Automation Evaluation Process!

Customer Stories

Better Service Starts Here

As a Level 4 Fanuc Servicing Integrator, Matrix has the ability to work on any Fanuc robot system for emergency service, spare parts, or reprogramming needs.