About

Power Generation

Matrix supports manufacturers building the components and subsystems that power large data centers, utilities, and industrial energy infrastructure across the United States. We integrate robotic automation that improves machine utilization, stabilizes quality, and reduces manual handling risk for heavy, high-precision parts. Our core capabilities include high-payload robotic machine tending, robotic metal finishing, engineered end of line automation, and inspection and traceability solutions designed for suppliers scaling capacity to meet accelerating data center and grid investment.

Types of Parts We Work With

These programs often involve heavy components with tight geometric requirements, controlled edge condition, and high expectations for repeatability.

Typical part families include:

- Gears, pinions, splined shafts, couplings, hubs, and rotating interfaces

- Transmissions, gearboxes, heavy housings, covers, and bearing carriers

- Structural frames, brackets, mounts, and fabricated assemblies used in generator and power system integration

- Thermal management and infrastructure components such as HVAC subassemblies, sheet metal enclosures, rack components, and related hardware that benefit from standardized handling and consistent pack out

Applications

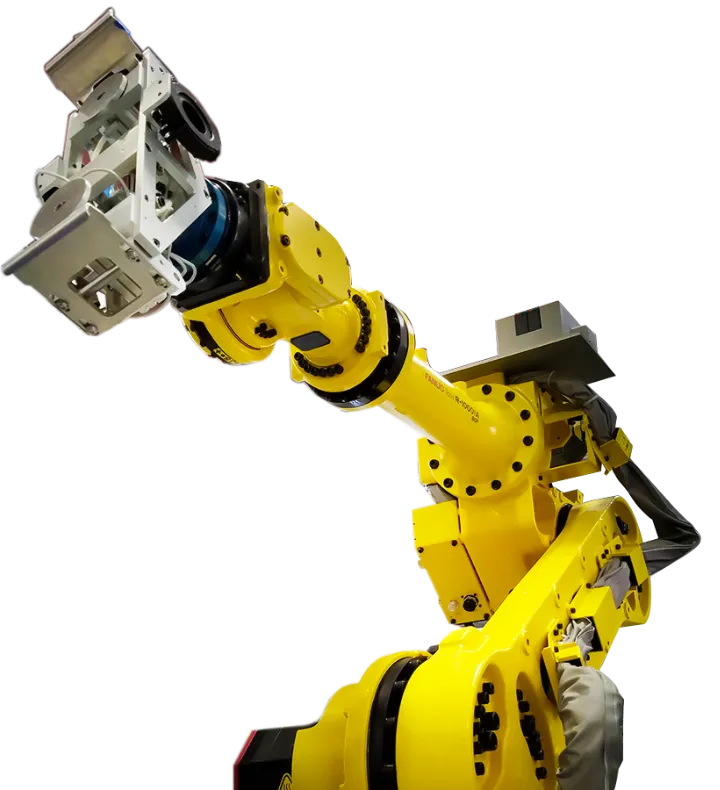

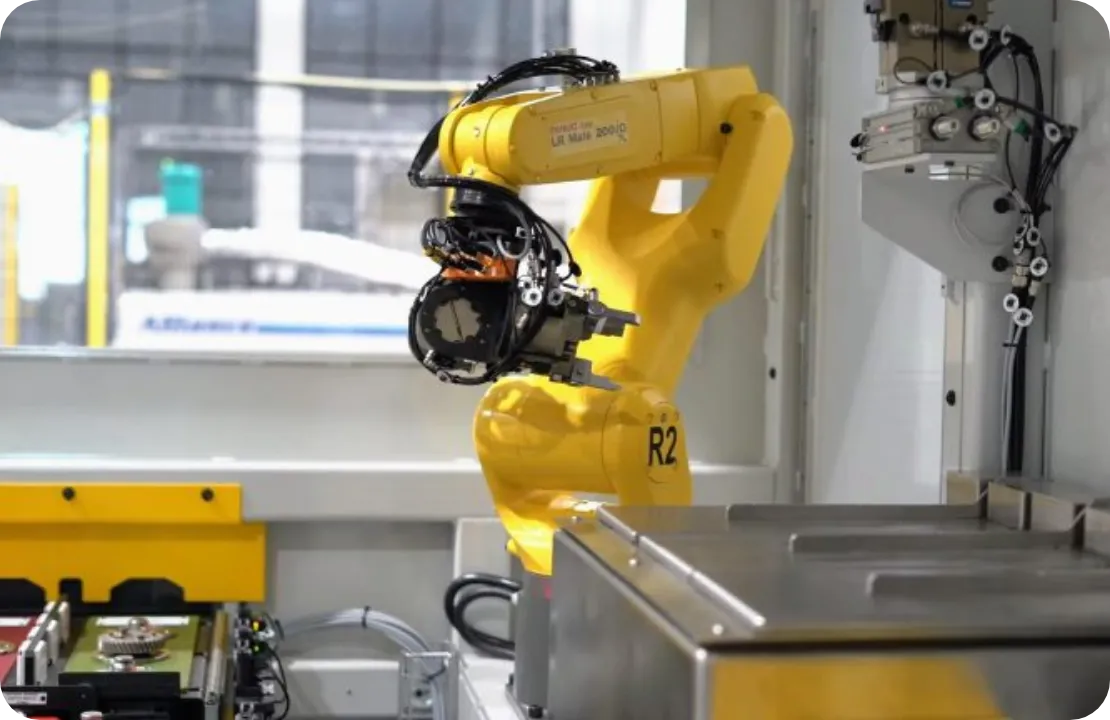

Robotic Machine Tending

Matrix designs and integrates high-payload tending cells for the machining processes common to power generation and infrastructure components. Systems are engineered for safe, repeatable handling of heavy parts while maintaining uptime and tolerance control across long production runs. Key features include:

- High-payload tending for hobbing, gear grinding, milling, turning, and related machining centers

- Rugged end-of-arm tooling and custom fixturing designed around high inertia parts and precise locating requirements

- Floor-level conveyors, carts, pallets, and drawer systems to support ergonomic part presentation and safe operator interaction

- Optional in-cell gauging and measurement with offset feedback to maintain tight tolerances and control tool wear effects

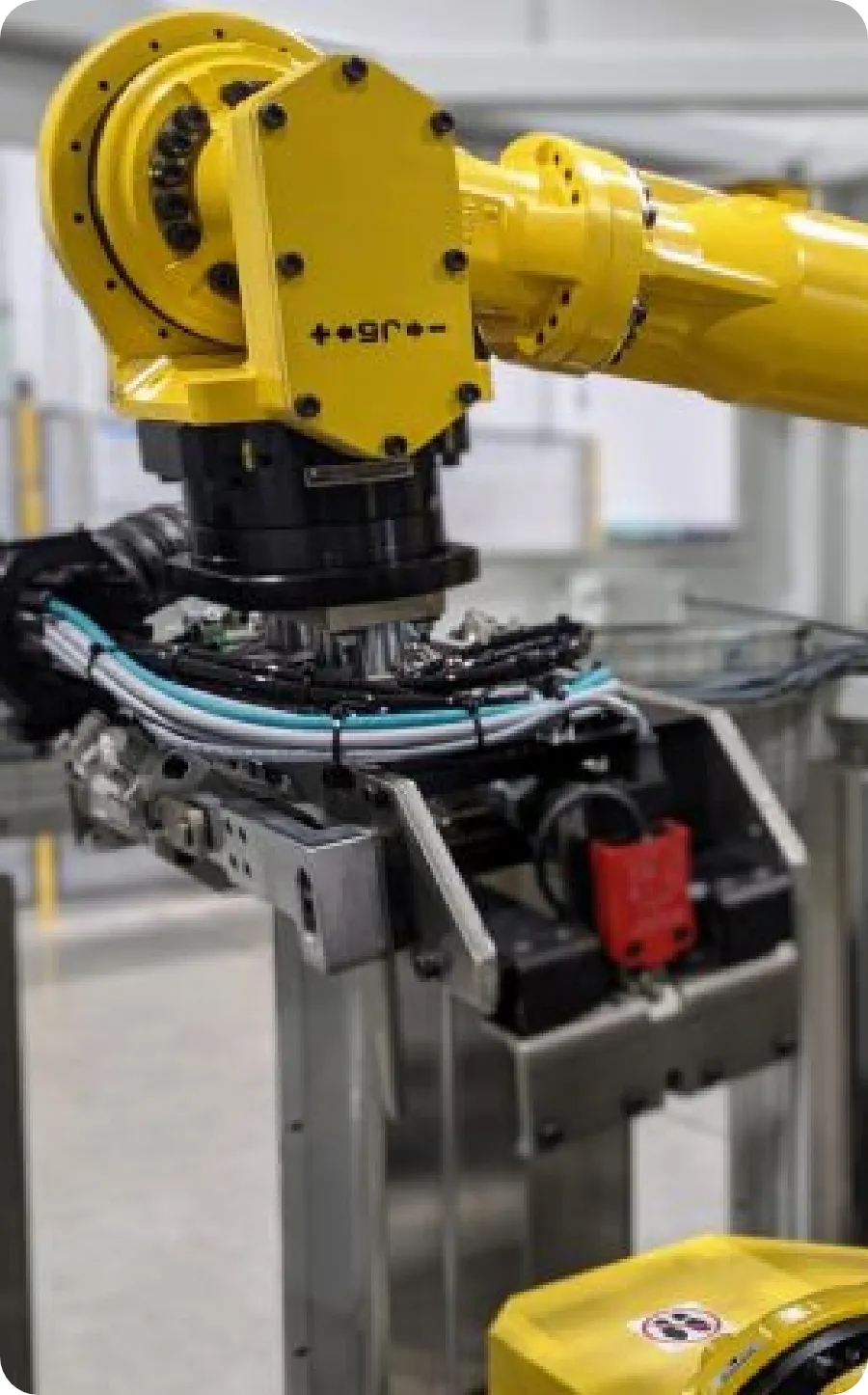

Robotic Metal Finishing (Deburring & Grinding)

We deliver robotic deburring, polishing, blending, and chamfering solutions that create consistent edge condition and surface quality on gears, shafts, housings, and related components. Projects can begin in the Matrix Deburr Lab to validate and de-risk tooling, abrasives, and cycle parameters before system build. Typical capabilities include:

- Automated edge prep, chamfering, and deburring for gear teeth features, shaft edges, and housing interfaces

- Deburr Lab validation of abrasives, spindle selection, feed, force, and RPM to reduce technical risk

- Force-control compliance tooling options to maintain consistent contact and finish across variable geometries

- Abrasive selection and process tuning optimized for tool life, stable finishes, and predictable cycle times

End of Line Automation

Matrix designs end of line automation that protects heavy components, standardizes packaging quality, and prevents bottlenecks between final operations and shipment. Systems are engineered for secure handling and consistent identification, including:

- Robotic palletizing and securement of heavy parts using protective packaging, dunnage, and controlled placement

- Integrated stretch wrapping and labeling to support shipping requirements and downstream identification

- Conveyors and heavy-load transfer systems to stabilize flow and reduce manual material movement

Inspection & Traceability

For suppliers that need tighter quality controls and better production visibility, Matrix integrates inspection and data capture into cells and end of line systems. Options include:

- Vision systems for geometry checks, feature presence verification, and basic defect detection where applicable

- Plant system integration options for SPC/NOK, production monitoring, and traceability reporting

Business Problems We Solve

Suppliers supporting data centers and large power systems are under pressure to scale throughput while maintaining tight quality and delivery performance.

Key challenges we address include:

- Maintaining tight tolerances and finish requirements on heavy components at higher production volumes

- Ergonomic and safety risks created by manual handling of large, high inertia parts

- Throughput bottlenecks between machining, finishing, inspection, and shipment staging

- Process variation and rework driven by inconsistent manual deburring and edge conditioning

- Limited production visibility without integrated inspection, traceability, and reporting

Why Power Generation Teams Choose Matrix

- Proven finishing solutions for gears, shafts, housings, and rotating equipment interfaces using validated processes

- Deep integration experience with gear-making and machining equipment, including support for machine tending with in-cell gauging and offset feedback

- End of line automation capability that standardizes packaging, labeling, and shipment readiness for heavy parts

- Scalable cell platforms that help suppliers expand capacity while maintaining repeatable quality and predictable throughput

Matrix’s power generation automation solutions are built for manufacturers scaling output to support U.S. data center growth while maintaining precision, uptime, and safe handling. By combining validated finishing processes, robust machine tending, and engineered end of line flow, we help suppliers increase throughput, reduce risk, and deliver consistent quality from machining through shipment.

Free Evaluation

Free Automation Evaluation Process

Have you ever thought about automating but weren’t sure where to start?

Contact us to go through our completely free Automation Evaluation Process.

By the end of this proven process, you will have a better understanding of how and where automation could fit into your current manufacturing operations.

Contact us to start your free Automation Evaluation Process!

Customer Stories

Better Service Starts Here

As a Level 4 Fanuc Servicing Integrator, Matrix has the ability to work on any Fanuc robot system for emergency service, spare parts, or reprogramming needs.