About

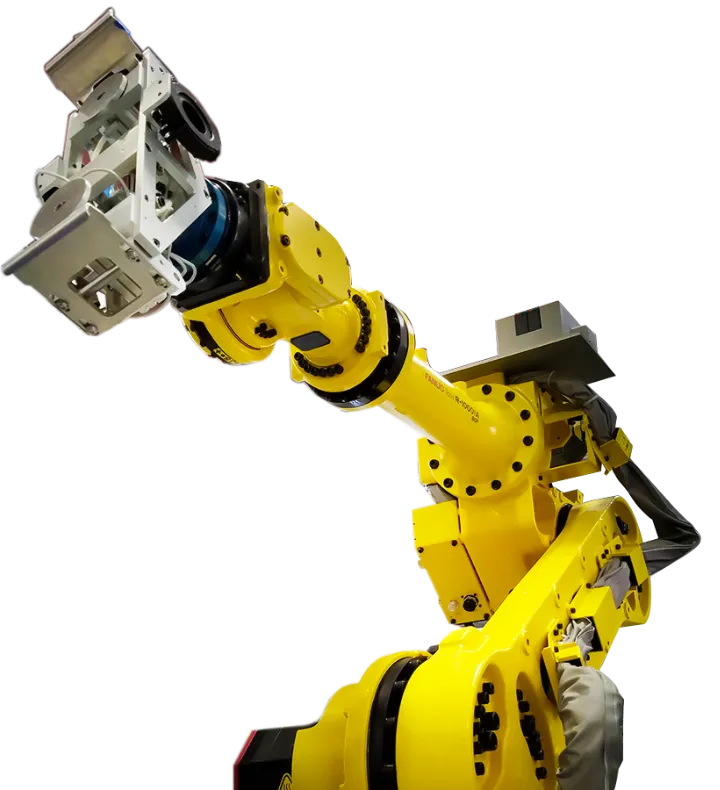

Robotic Deburring & Metal Finishing Systems

Matrix Design delivers precision robotic deburring, robotic grinding, and robotic metal finishing systems that improve consistency, safety, and throughput on the production floor.

Our systems replace manual deburring, polishing, and grinding operations that are labor-intensive, variable due to human error, and difficult to scale without quality risks. With a validation-first approach and proven finishing technologies, we help manufacturers reduce scrap, stabilize surface results, and redeploy skilled labor to higher value work.

What We Deliver:

- Turnkey robotic deburring systems

- Custom robotic grinding and finishing cells

- Integrated gauging, part handling, cleaning, and part marking where required

- In-house testing, validation, and R&D through the Matrix Deburr Lab

Parts We Commonly Work With

Our robotic finishing systems are designed for a wide range of part types and materials, including:

- Precision machined components

- Aluminum and iron castings

- Aerospace structures and brackets

- Suspension knuckles and control arms

- Engine blocks and transmission housings

- Structural weldments and housings

- Plumbing fixtures and other complex component families

Whether the goal is sharp edge removal, controlled edge break, chamfer creation, or consistent grinding finishes, Matrix systems are engineered to deliver repeatable outcomes.

Removing Sharp Edges, Adding Chamfers, and Breaking Edges – Robotically

Manual edge finishing introduces variation and quality issues. Matrix robotic systems ensure every part is:

- Deburred consistently

- Finished with a controlled edge break or chamfer

- Inspected for quality with vision or gauging

- Completed with minimal operator interaction

These systems are ideal for applications where repeatability and surface integrity are non-negotiable.

Matrix Deburr Lab – Testing Your Parts In-House

Before you commit to automation, we prove it works. In our dedicated Robotic Deburr Lab, we evaluate your parts and develop a robust robotic process, including:

- Burr classification and removal pathing

- Tool selection and optimization

- Robotic programming and force profiling

- Video documentation and performance reports

You’ll get real-world results before the full project is kicked off to validate tooling, cycle times, and quality outcomes.

Advanced Touch Detection & Force Control Technology

Matrix automated finishing systems include touch detection and force compliance features that let your robot adapt to part surfaces dynamically:

- Maintain consistent tool pressure

- Automatically detect part presence and location

- Prevent over-grinding or under-deburring

- Prevent excessive wear on tools, increasing tool life

- Maintain a consistent finish on the parts across the tool’s entire life

- Compensate for part or fixturing variations

This level of precision ensures the robotic deburring and finishing process remains stable over thousands of parts.

Tooling We Integrate with Robotic Finishing Systems

We work with top-tier finishing and spindle technology partners to meet your part’s exact requirements. Common tool brands we integrate:

- PushCorp compliant force-control spindles

- 3M, Norton Abrasives, FER, and other abrasive suppliers

- Matrix-custom EOAT (end-of-arm tooling) for grinding and deburring

Whether you’re finishing aluminum castings or hardened steel, we’ll select the right tool for the job.

Automotive Expertise – Standard & Custom Robotic Systems

Matrix has deep experience delivering robotic deburring and grinding systems to Tier 1 and OEM automotive customers. Sample applications include:

- Deburring suspension knuckles and control arms

- Robotic grinding of transmission housings

- Automated finishing of EV battery enclosures and brackets

These cells are designed with fast cycle times, high uptime, and quality repeatability for high-volume production.

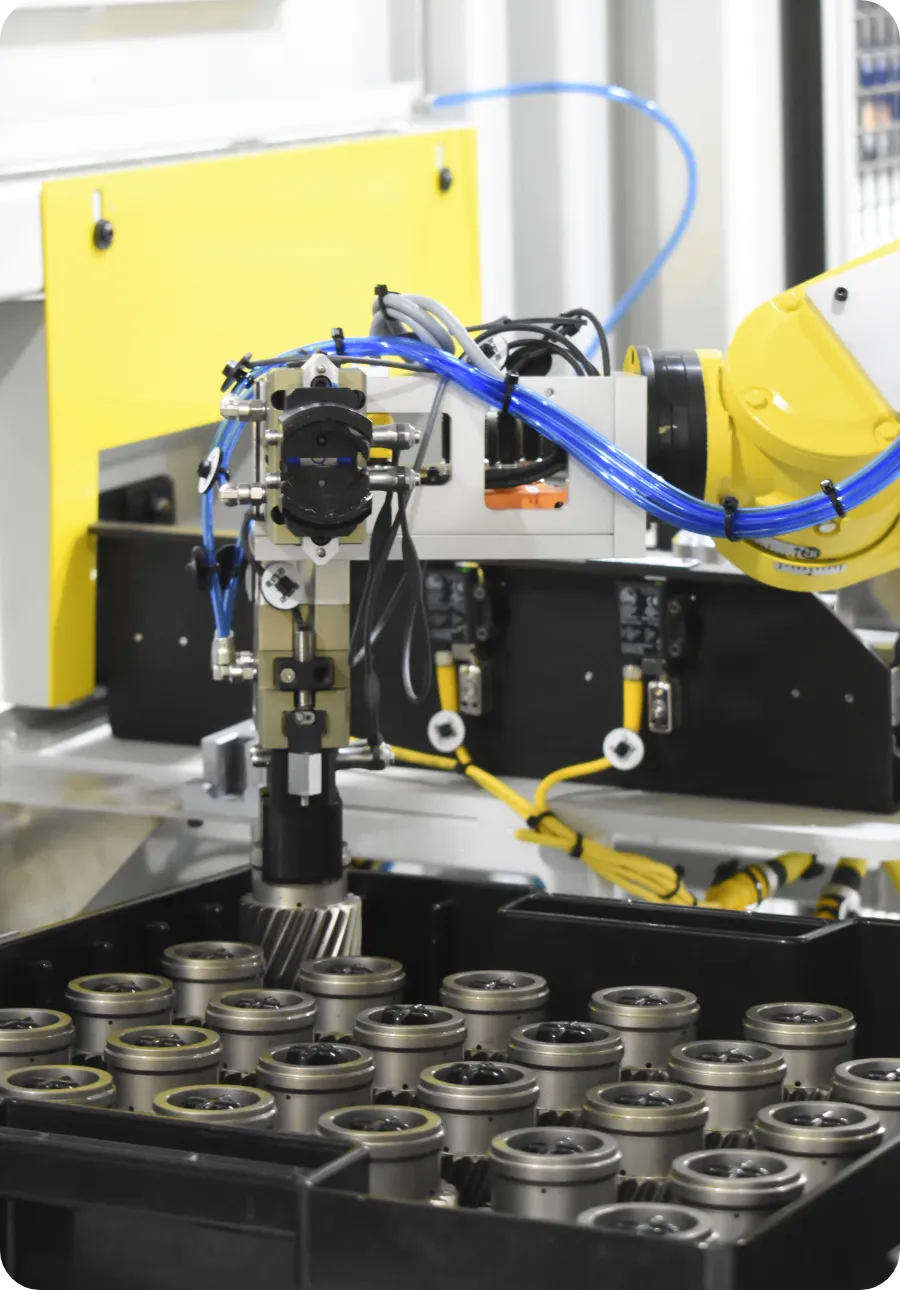

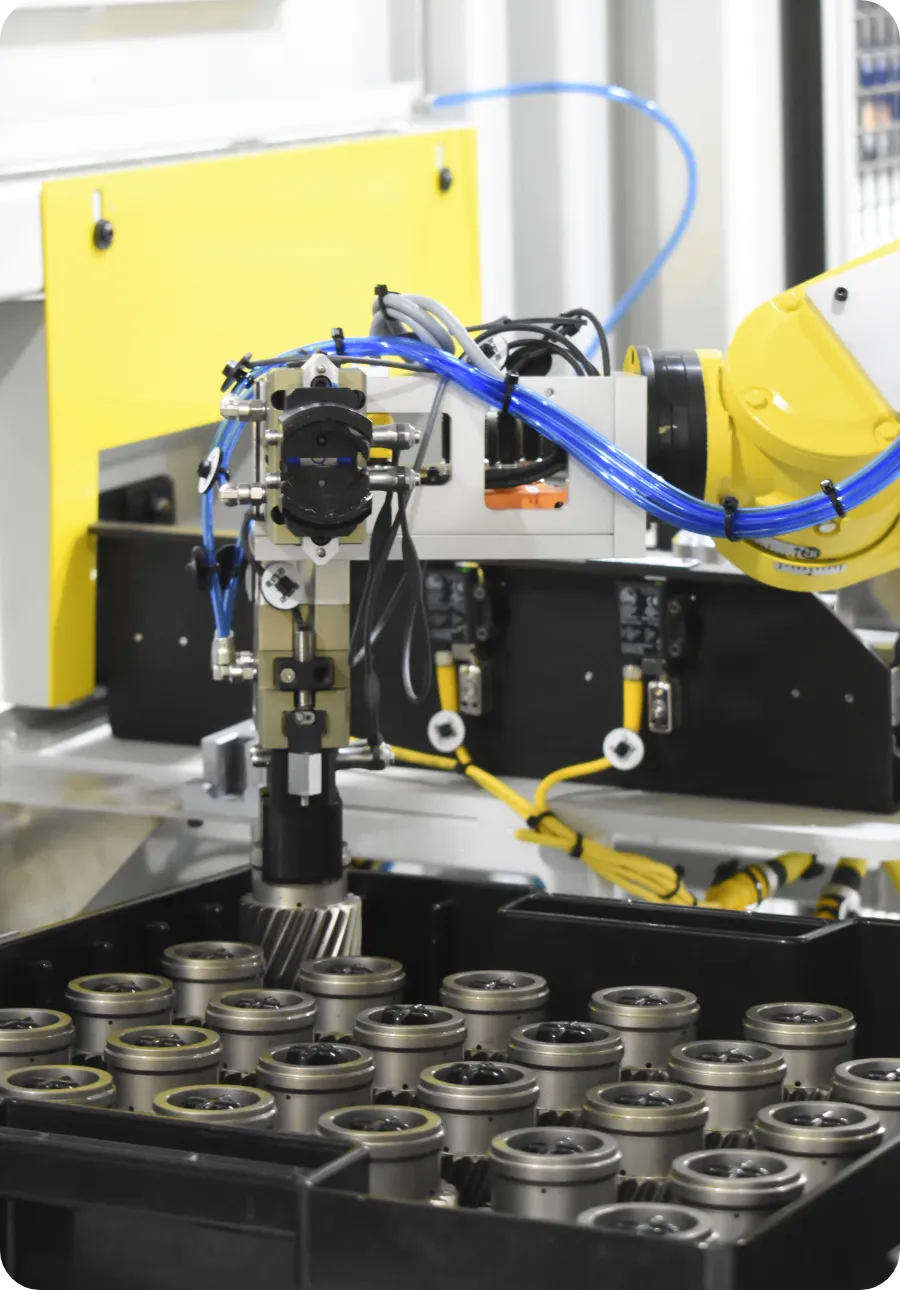

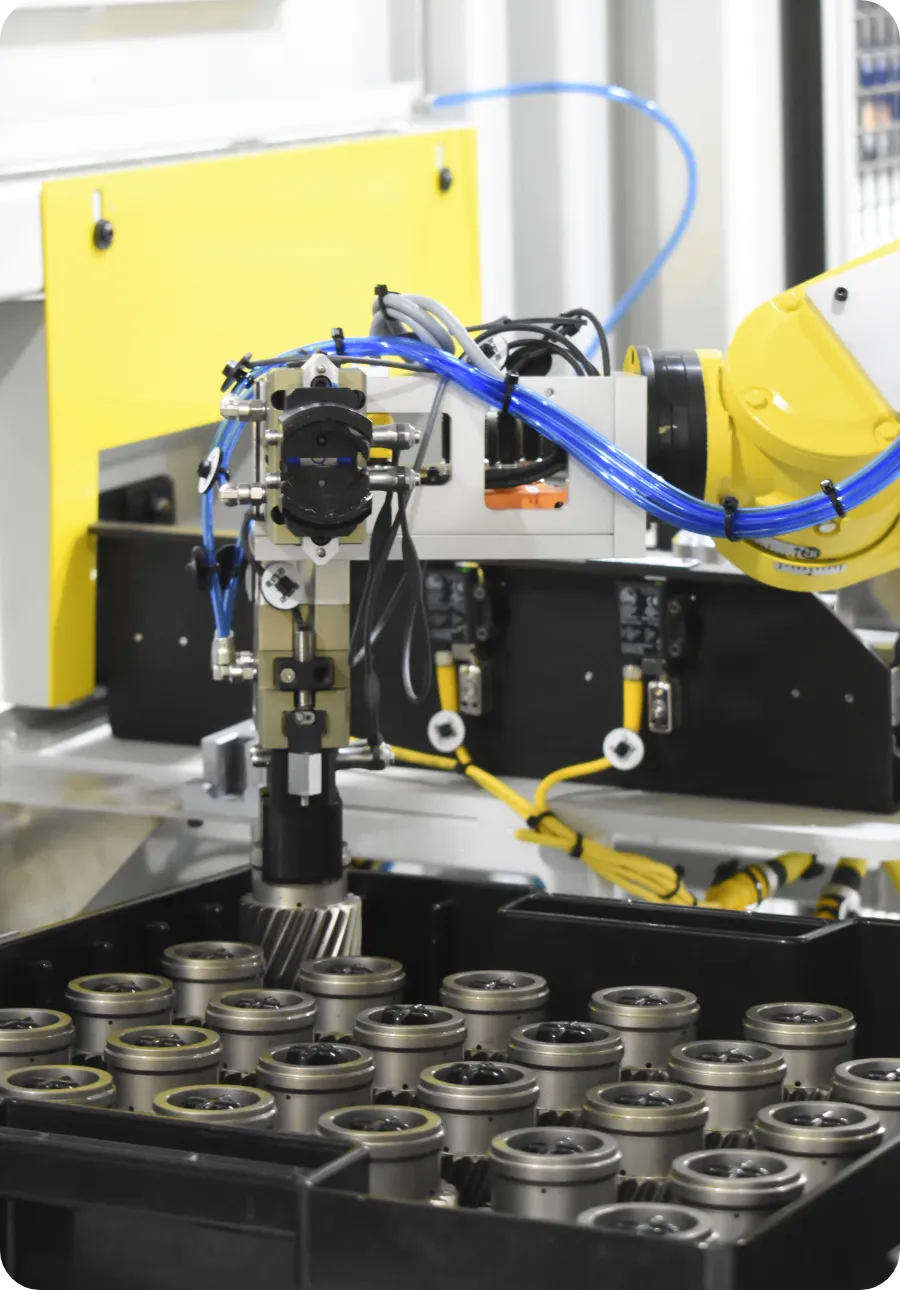

Combined Robotic Processes – Deburr, Tend, and Gauge with One Robot

Matrix excels at building multi-function robotic cells that do more than just finish parts. A single robot can:

- Tend a CNC machine

- Deburr or grind the part

- Gauge for quality or edge radius

- Mark or package the finished part

This approach reduces footprint, saves cost, and increases automation ROI.

Industries We Serve with Robotic Metal Finishing

We support a wide range of industries with robotic finishing systems:

Common Challenges We Help Solve

- Shortage of skilled labor to manually deburr or grind parts

- Inconsistent finish quality across shifts or operators

- Difficulty handling large or awkward parts

- Unreliable results using basic finishing equipment

- Unsafe, noisy, or ergonomic issues with manual deburring

With Matrix, you get a robotic solution that works: proven, tested, and repeatable.

Free Evaluation

Free Automation Evaluation Process

Have you ever thought about automating but weren’t sure where to start?

Contact us to go through our completely free Automation Evaluation Process.

By the end of this proven process, you will have a better understanding of how and where automation could fit into your current manufacturing operations.

Contact us to start your free Automation Evaluation Process!

Customer Stories

Better Service Starts Here

As a Level 4 Fanuc Servicing Integrator, Matrix has the ability to work on any Fanuc robot system for emergency service, spare parts, or reprogramming needs.