About

Defense – Robotic Automation

Matrix supports defense OEMs and suppliers by integrating robotic automation that improves repeatability, stabilizes quality, and increases throughput for both precision-machined components and larger assemblies. Focused on developing robotic metal finishing, machine tending, and engineered end of line handling solutions, Matrix collaborates with manufacturers to make sure the documentation, traceability, and compliance standards are met. Matrix is an ITAR registered organization, enabling us to support ITAR-related machine tending, metal finishing, inspection, and pack out operations.

Types of Parts We Work With

Defense programs often include a mix of tight-tolerance machined parts and heavier assemblies that still require controlled edge condition and safe handling.

Typical components include:

Defense programs often include a mix of tight-tolerance machined parts and heavier assemblies that still require controlled edge condition and safe handling. Typical components include:

- Precision-machined housings, mounts, and drivetrain components

- Larger castings and welded assemblies requiring deburring, edge prep, or grinding

- Mechanical subassemblies and kitted components that require handling, labeling, and serialization at pack out

- Fabrications, frames, and support structures where consistent edge break and damage prevention are critical

Applications

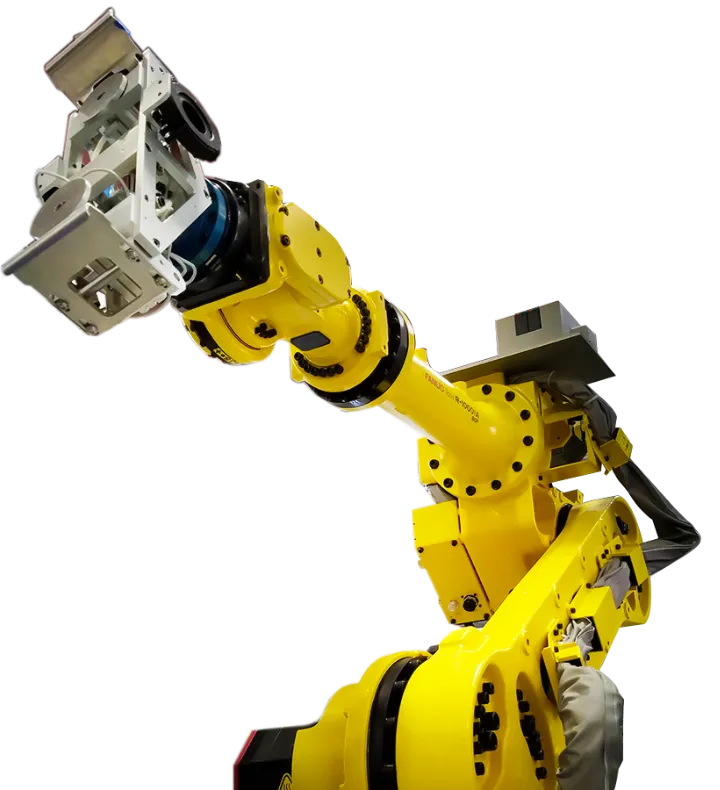

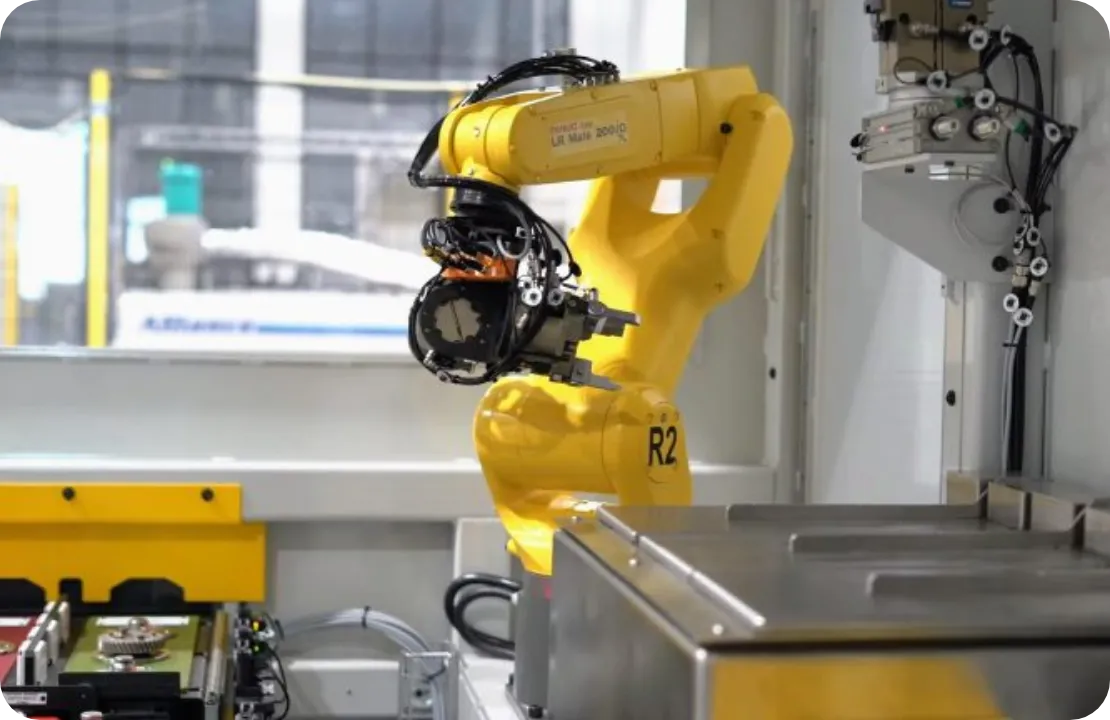

Robotic Machine Tending

For defense machining operations that need increased machine utilization and consistent handling, Matrix integrates industrial and collaborative tending cells for CNCs, grinders, presses, CMMs, washers, and related equipment. These systems are designed to support repeatability, in-process verification, and controlled changeover for repeatable part families. Key features include:

- Automated tending for CNCs, grinders, presses, and secondary operations

- Quick-change end-of-arm tooling to support multiple part types and program variation

- Robust fixture design and optional in-cell gauging / measurement to maintain repeatability and reduce downstream inspection burden

- Offset feedback to machine tools to help maintain compliance as tools wear over production runs

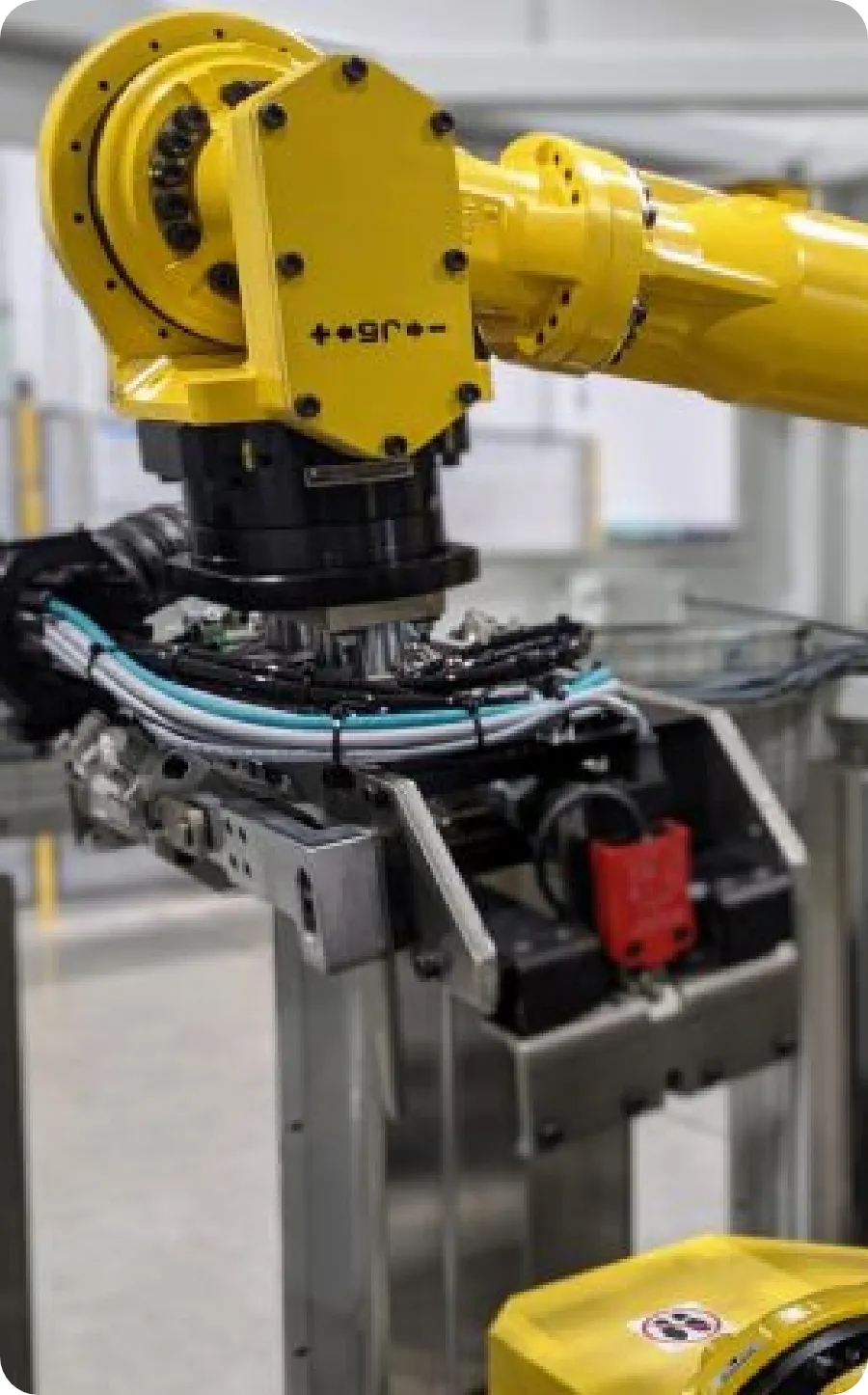

Robotic Metal Finishing (Deburring & Grinding)

Matrix delivers robotic deburring, chamfering, and grinding solutions for defense components where consistent edge condition and controlled finishes are required. Projects can begin in the Matrix Deburr Lab to classify burrs, select tools and abrasives, and validate parameters such as feed, force, and RPM to reduce risk before system build. Typical capabilities include:

- Burr removal and chamfer processes developed and proven prior to deployment

- Integrated compliance tooling with optional force sensing to maintain consistent contact on delicate or tolerance-critical features and maximize tool / media life

- Toolpath strategies designed for repeatability and controlled edge condition across part families

- Optional vision checks for feature verification and process confirmation before parts leave the cell

End-of-Line Handling & Packaging

Matrix designs end of line automation systems that are engineered to prevent damage and maintain traceable movement into staging or shipping, including for ITAR-controlled work. Solutions often include:

- Robotic palletizing and protected handling of components and subassemblies using dunnage and controlled placement

- Conveyors, AMRs, shuttles, and transfer systems to streamline flow to staging, kitting, or shipping

- Labeling and serialization integration to support program compliance and downstream identification requirements

Inspection & Traceability

For programs requiring verification and audit-ready records, Matrix integrates inspection and data capture into finishing, tending, and end of line systems. This supports quality containment, documentation, and process visibility. Options include:

- Vision inspection and feature verification tied to plant quality systems

- Data logging for part images, pass and fail records, and process history required for program documentation

- Integration with plant MES and ERP systems where applicable, including secure network considerations

Business Problems We Solve

Defense customers often need automation that produces consistent results while meeting documentation and schedule constraints.

Key challenges we address include:

- Ensuring repeatability and documentation across production sites and shifts

- Reducing ergonomic risk and manual variability in repetitive machine tending and grinding operations

- Maintaining spec compliance over time with in-process verification and controlled finishing methods

- Launching automation on tight program schedules while reducing technical and integration risk

- Supporting traceability, labeling, and identification requirements that enable audits and downstream accountability

- Executing ITAR-related automation projects with an ITAR-registered partner

Why Defense Teams Choose Matrix

- ITAR registered capability to support automation for ITAR-controlled parts, processes, and pack out flows

- Disciplined program execution process with documentation rigor aligned to audited manufacturing environments

- Proven finishing methods validated before build to reduce risk and improve first-time success

- Strong experience integrating with CNCs, grinders, presses, and plant-floor systems in controlled environments

- Cell designs that support repeatability through fixturing, verification options, and stable process control

Matrix’s defense automation solutions are built for programs where consistency, documentation, and controlled execution are essential. By validating metal finishing processes upfront and integrating robust machine tending, inspection, and end of line handling cells, we help teams reduce risk, improve throughput, and maintain repeatable quality throughout the program lifecycle.

Free Evaluation

Free Automation Evaluation Process

Have you ever thought about automating but weren’t sure where to start?

Contact us to go through our completely free Automation Evaluation Process.

By the end of this proven process, you will have a better understanding of how and where automation could fit into your current manufacturing operations.

Contact us to start your free Automation Evaluation Process!

Customer Stories

Better Service Starts Here

As a Level 4 Fanuc Servicing Integrator, Matrix has the ability to work on any Fanuc robot system for emergency service, spare parts, or reprogramming needs.