About

End of Line Automation

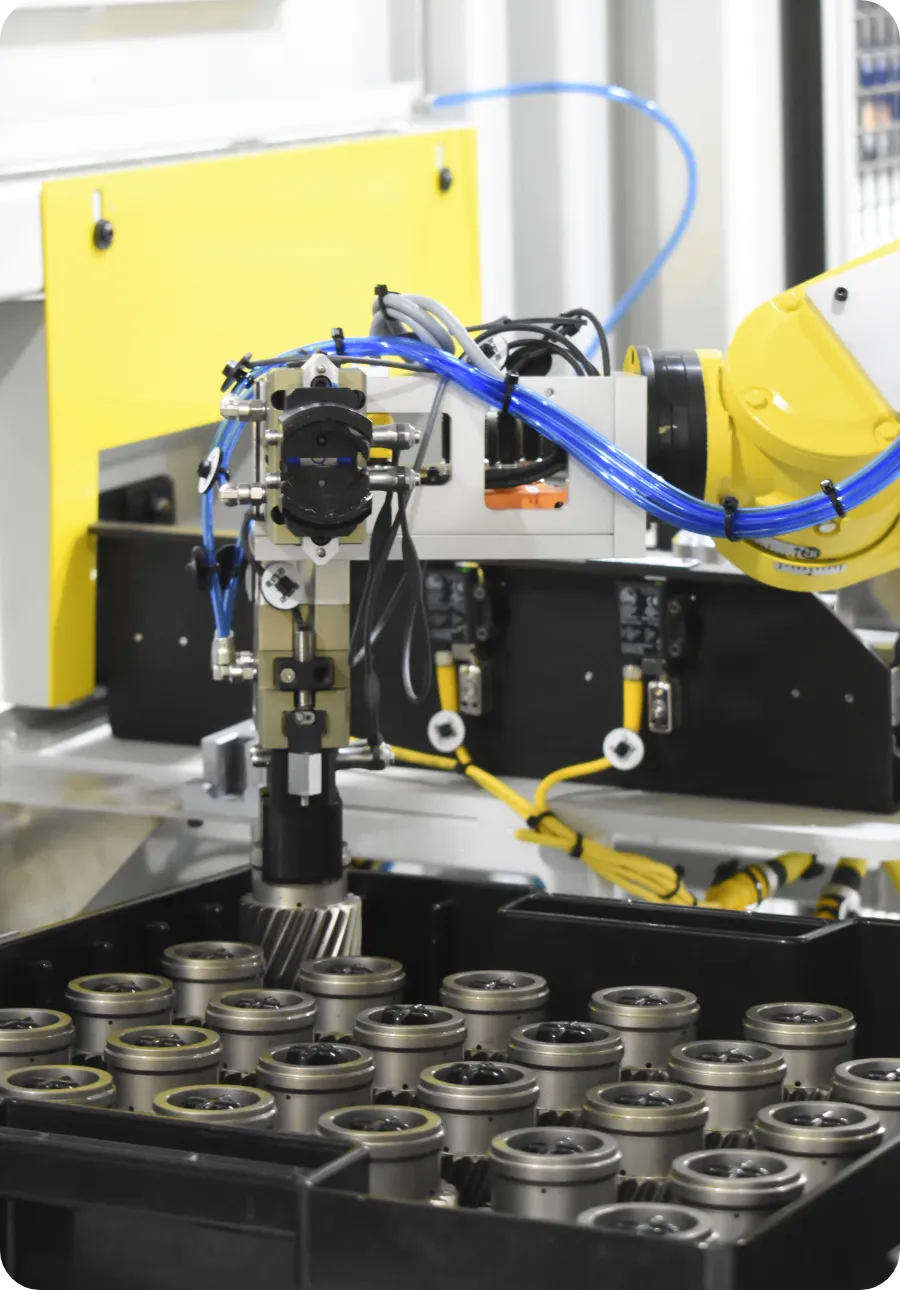

Matrix helps manufacturers reduce labor dependency, improve consistency, and increase throughput by integrating robotic packaging and material handling systems into secondary and tertiary packaging operations. We design engineered end of line solutions that automate case packing, labeling, palletizing, wrapping, and custom conveyance / routing so finished goods move through pack out with predictable execution and minimal manual touch labor.

What We Deliver:

Matrix provides complete end of line automation programs from concept through launch, including:

- Comprehensive end of line automation systems for secondary and tertiary packaging

- Robotic case packing solutions for a wide range of product and pack configurations

- Robotic palletizing cells with integrated stretch wrapping

- Print and apply labeling with barcode scanning and verification workflows

- Vision inspection and verification to prevent nonconforming products from moving downstream

- Custom conveyor integration, accumulation, merges, and routing logic

- System simulation, controls design, safety design, and commissioning support

Common Business Challenges We Help Solve

End of line packaging is often where production output is constrained. Manual packing, labeling, and palletizing create ergonomic risk, quality variation, and capacity limits that show up as line stoppages and rework. Matrix addresses these challenges by engineering systems that:

- Eliminate repetitive manual work through robotic case packing, palletizing, and wrapping automation

- Improve accuracy and consistency of case packing patterns, label placement, and verification steps

- Enable traceability and output reporting with integrated vision, barcode scanning, and print and apply labeling

- Reduce changeover time using recipe management, adjustable tooling, and standardized operator interfaces

- Scale throughput using accumulation, merges, transfers, and flexible routing integrated with conveyors and upstream equipment

- Support facility material flow with options to integrate pallet transfer, staging interfaces, and mobile automation such as AMRs where applicable

Core Capabilities

Matrix provides complete end of line automation and integration services, including:

- Robotic packaging and case packing

- Automated case forming and case handling integration

- Robotic palletizing and depalletizing

- Stretch wrapping and load securement integration

- Tray, carton, and case loading

- Conveyor integration, accumulation, and flow control

- Part orientation, presentation, and verification

- Vision-based inspection and quality control

- Print and apply labeling with barcode verification

- Line synchronization and data connectivity with MES and ERP systems

Packaging Formats and Products We Commonly Support

Matrix end of line systems are designed for repeatable secondary and tertiary packaging workflows across a broad range of products and packaging formats, including:

- Corrugated cases, trays, cartons, pouches, cans, and shipper boxes

- Bundles and multipacks feeding into cases

- Consumer packaged goods and packaged assemblies

- Kitted products requiring verified contents before sealing

- Durable goods and components packaged into cartons, cases, or totes

- Custom product carriers, nests, dunnage, and fixtures

Industries We Support with End of Line Automation

Matrix supports end of line automation across industries where packaging consistency and throughput are critical, including:

- Automotive and mobility components

- Aerospace and defense components

- Heavy equipment and industrial components

- Consumer products and durable goods

- Food and beverage secondary and tertiary packaging operations

- Contract manufacturing and co-packing environments

Typical End of Line System Building Blocks

End of line projects vary by product, packaging format, and throughput requirements, but most systems combine a set of proven building blocks:

- Case forming and presentation: case erecting integration, squaring, and controlled delivery to pack stations

- Packing and verification: robotic or automated loading with checks for presence, weight, orientation, or count verification

- Sealing and labeling: tape or adhesive sealing integration, print and apply labeling, and scan verification workflows

- Palletizing and wrapping: robotic palletizing patterns, slip sheet or tier sheet integration where needed, and stretch wrapping integration

- Material handling and routing: accumulation, merges, transfers, and conveyor logic to maintain steady throughput and reduce stoppages

- Data capture and reporting: barcode scans, vision results, and production counts logged for traceability and performance visibility

Case Packing and Labeling

Matrix integrates case packing and labeling systems that reduce manual labor and improve consistency at the point where packaging errors are most costly. Typical system features include:

- Controlled product placement into cases, trays, or cartons to maintain consistent pack configuration

- Automated case handling and routing to balance flow between packing, sealing, and labeling operations

- Print and apply labeling with barcode verification to confirm correct identification before the case proceeds

- Exception handling workflows to divert, re-label, or re-verify cases that fail inspection or scan verification

- Optional vision checks to confirm label presence and placement or to validate pack configuration

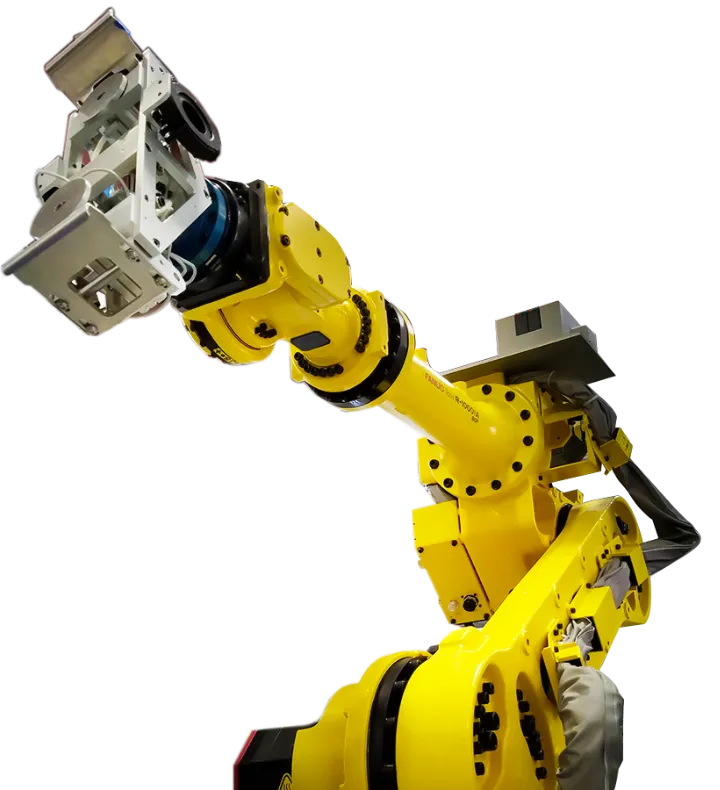

Robotic Palletizing and Load Securement

Matrix integrates palletizing and wrapping solutions that reduce manual handling and stabilize end of line output. Systems are engineered for continuous operation and practical maintenance, including:

- Robotic palletizing with repeatable patterns and recipe selection based on product or packaging format

- Integration of slip sheet, tier sheet, and corner board options where required by the load build

- Stretch wrapping integration to complete the end of line process and reduce manual wrapping

- Pallet transfer and conveyor integration to maintain flow into and out of the palletizing cell

- Safety and access concepts designed for reliable operation and operator-friendly fault recovery

Vision, Verification, and Traceability

Matrix uses vision and identification systems to prevent packaging errors and provide end of line visibility. Capabilities can include:

- Barcode scanning and verification tied to the active recipe and packaging format

- Vision inspection for presence checks, orientation verification, and label placement confirmation

- Data logging for production counts, pass and fail results, and packaging events

- Optional connectivity to MES or ERP systems for reporting, traceability, and performance dashboards

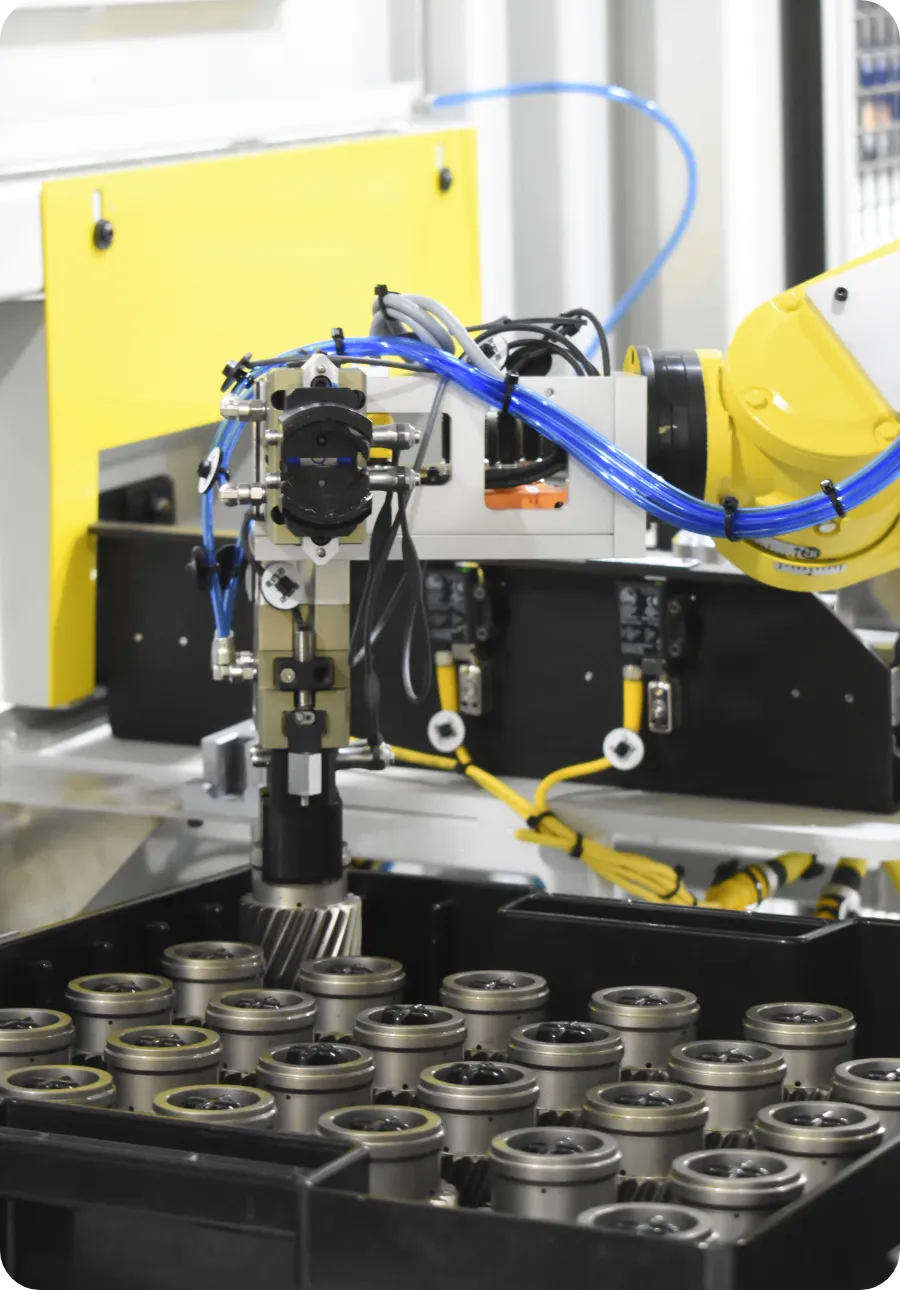

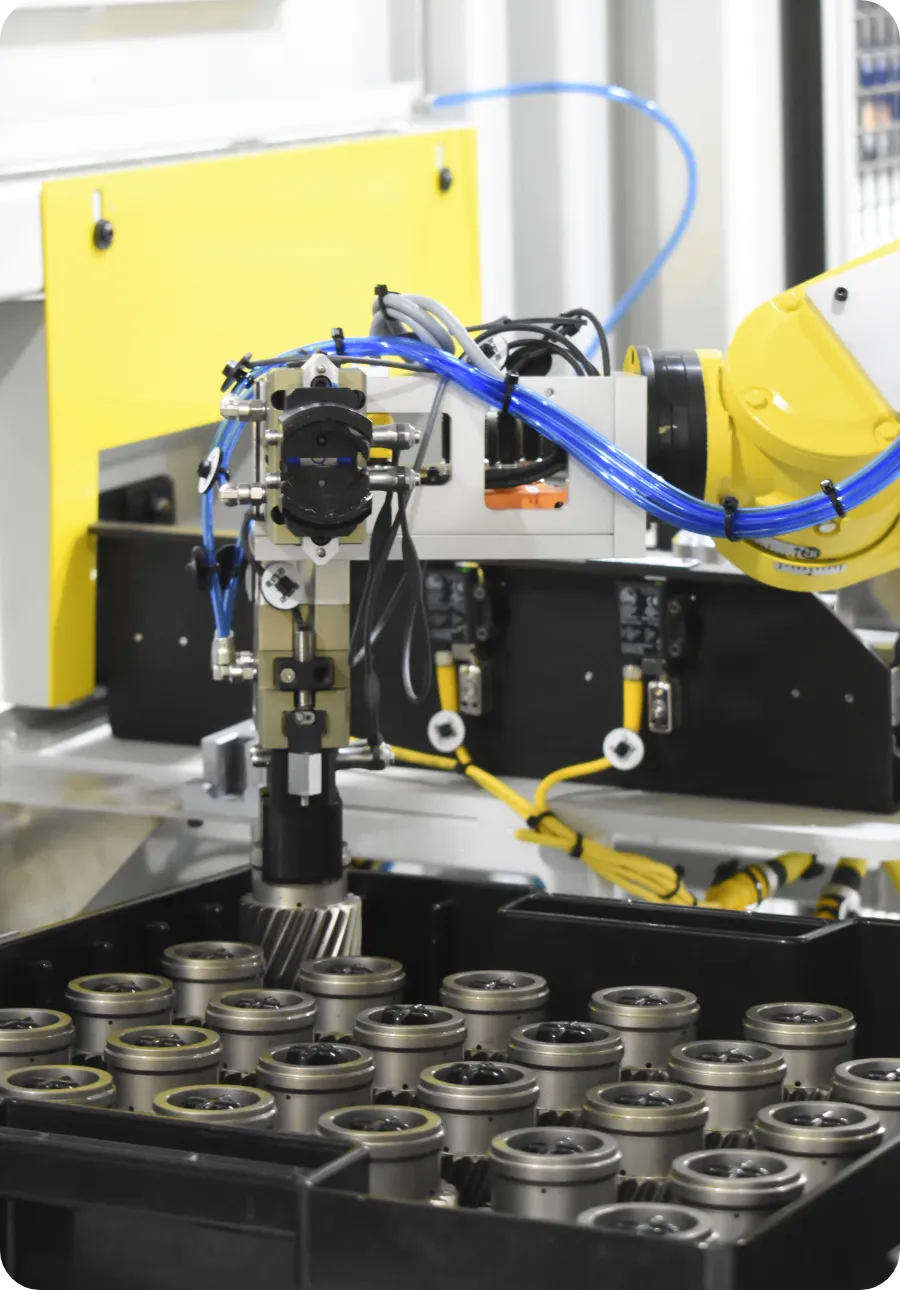

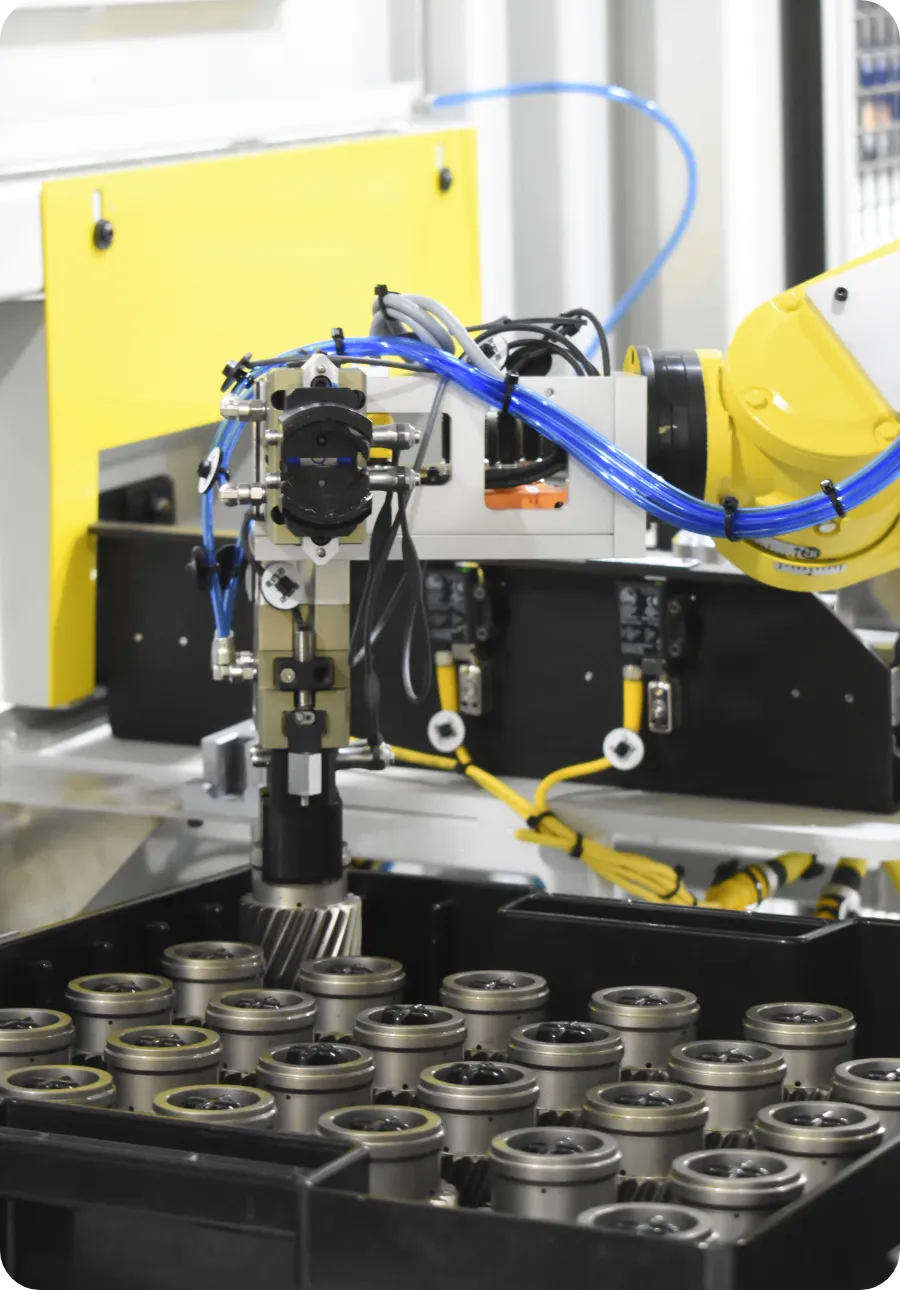

Industries We Serve with Robotic Metal Finishing

We support a wide range of industries with robotic finishing systems:

Common Challenges We Help Solve

- Shortage of skilled labor to manually deburr or grind parts

- Inconsistent finish quality across shifts or operators

- Difficulty handling large or awkward parts

- Unreliable results using basic finishing equipment

- Unsafe, noisy, or ergonomic issues with manual deburring

With Matrix, you get a robotic solution that works: proven, tested, and repeatable.

Free Evaluation

Free Automation Evaluation Process

Have you ever thought about automating but weren’t sure where to start?

Contact us to go through our completely free Automation Evaluation Process.

By the end of this proven process, you will have a better understanding of how and where automation could fit into your current manufacturing operations.

Contact us to start your free Automation Evaluation Process!

Customer Stories

Better Service Starts Here

As a Level 4 Fanuc Servicing Integrator, Matrix has the ability to work on any Fanuc robot system for emergency service, spare parts, or reprogramming needs.