Top 10 Applications of Pick-and-Place Automation Across Different Industries

In an era where efficiency and precision are paramount, pick-and-place automation has emerged as a transformative technology across various industries. This white paper explores the top ten applications of pick-and-place automation and highlights how Matrix Design LLC’s advanced solutions can meet the unique needs of your industry.

1. Electronics Assembly

In the electronics industry, the demand for high-speed, precise component handling is critical. Pick and place automation equipment excels in this environment by quickly and accurately placing tiny components onto circuit boards. This reduces production time and enhances the quality of electronic devices.

Matrix Design LLC provides cutting-edge pick and place automation systems designed for the electronics sector. Our solutions, including industrial pick and place robots, ensure efficient handling and assembly of delicate electronic parts. For more details on how our systems can streamline your electronics assembly, visit our pick and place automation page.

2. Food and Beverage Packaging

The food and beverage industry relies heavily on automation for packaging processes. Automation pick and place systems are used to handle and package various food items, from bottles to boxes, with high efficiency and accuracy. This minimizes waste and ensures compliance with safety standards.

Matrix Design LLC offers specialized pick place automation solutions tailored for the food and beverage sector. Our automated pick and place systems enhance packaging efficiency and hygiene, helping you meet industry standards. Learn more about our food and beverage automation solutions on our main automation page.

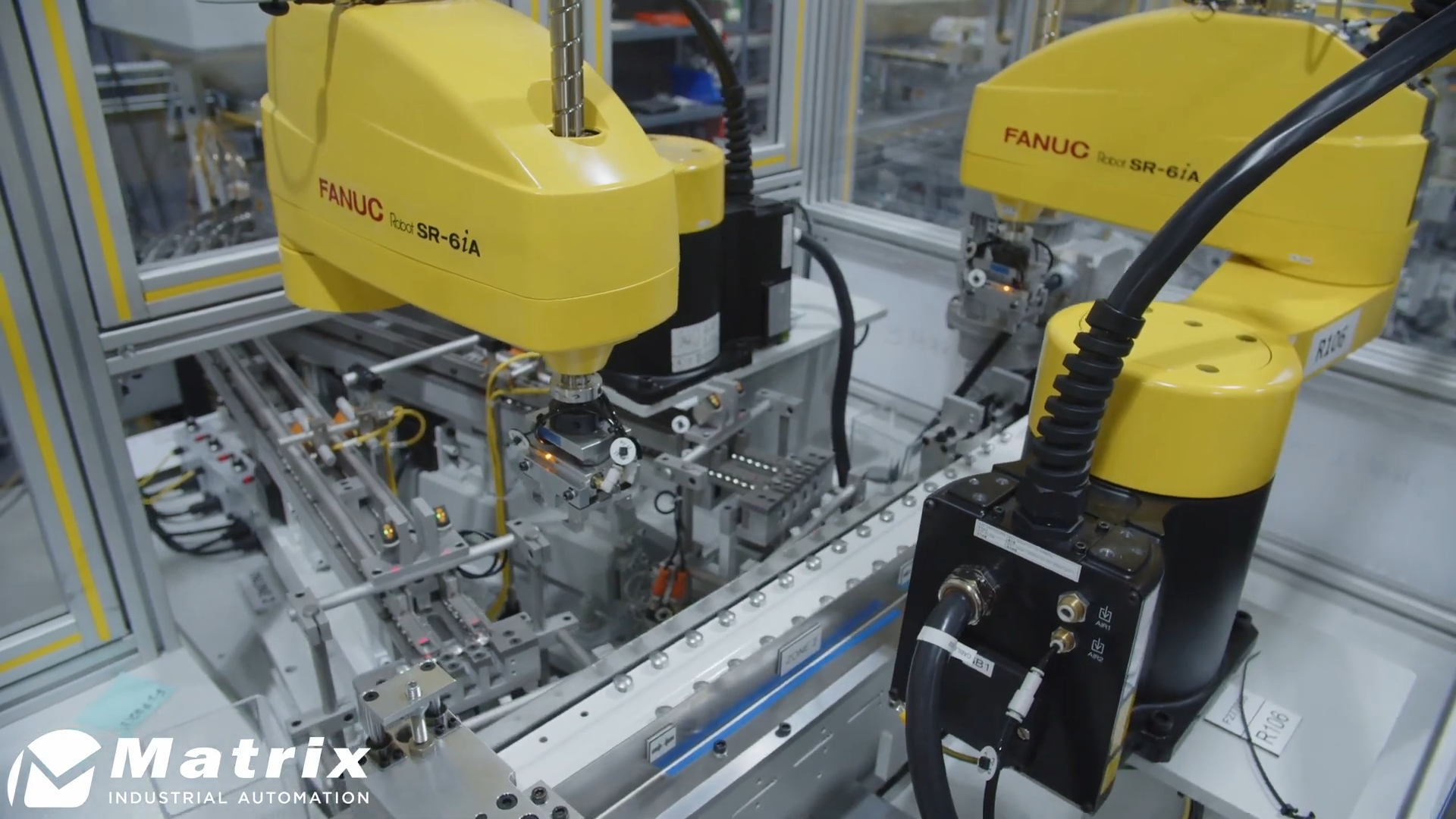

3. Automotive Manufacturing

In automotive manufacturing, pick-and-place automation is used to handle components and assemblies in a highly organized manner. From placing parts on assembly lines to managing components in production cells, these systems improve throughput and reduce manual labor.

Matrix Design LLC’s robotic pick and place systems are designed to meet the rigorous demands of automotive manufacturing. Our solutions, including the Fanuc pick and place robot, provide reliable and efficient handling of automotive parts. Explore how our automation solutions can enhance your automotive production by visiting our pick and place automation page.

4. Pharmaceutical Manufacturing

Precision and contamination control are crucial in pharmaceutical manufacturing. Pick and place automation equipment is used to handle and package pharmaceutical products while maintaining stringent cleanliness and accuracy standards.

At Matrix Design LLC, we offer advanced pick and place automation systems that cater to the pharmaceutical industry’s specific needs. Our automated pick and place solutions help ensure high standards of hygiene and precision. Discover more about our pharmaceutical automation solutions on our main automation page.

New sensor technologies are enhancing the precision and reliability of part washing systems. Sensors can detect contaminants at a microscopic level and ensure that every component is cleaned to the highest standard. This advancement is crucial for industries requiring stringent cleanliness standards.

Matrix Design LLC incorporates cutting-edge sensor technology into our automated parts washers. Learn more about how our innovative systems can meet your cleanliness requirements on our Part Washing Automation page.

5. Consumer Goods

The consumer goods industry benefits greatly from pick-and-place automation in packaging and assembly processes. These systems are used to handle a wide range of products, from cosmetics to household items, with speed and efficiency.

Matrix Design LLC provides versatile pick and place loader solutions for the consumer goods sector. Our robotic pick and place systems streamline the handling and packaging of various consumer products, enhancing production efficiency. For more information on how our solutions can improve your consumer goods manufacturing, visit our pick and place automation page.

6. Medical Device Manufacturing

Medical device manufacturing requires utmost precision and adherence to safety standards. Pick and place automation systems are employed to handle delicate medical components and assemble devices with high accuracy.

Matrix Design LLC’s industrial pick and place robots are designed for the medical device industry, ensuring that your products are assembled with precision and care. Our automated pick and place solutions help maintain the high standards required in medical manufacturing. Learn more about our medical device automation solutions on our main automation page.

7. Aerospace Industry

In the aerospace industry, pick-and-place automation is used for handling and assembling complex components with high precision. These systems help manage parts and assemblies in a demanding and high-tech environment.

Matrix Design LLC offers robust pick and place automation equipment for the aerospace sector. Our robotic pick and place systems are designed to meet the stringent requirements of aerospace manufacturing. Explore how our solutions can enhance your aerospace production on our pick and place automation page.

8. Metalworking and Fabrication

In metalworking and fabrication, pick-and-place automation assists in handling heavy and bulky components. These systems streamline the movement of metal parts and assemblies, improving efficiency and reducing manual handling.

Matrix Design LLC’s pick and place automation systems are engineered to handle the demands of metalworking and fabrication. Our solutions, including the Fanuc pick and place robot, are designed to manage heavy and complex components with ease. Discover more about our metalworking automation solutions on our main automation page.

9. Logistics and Warehousing

Pick-and-place automation plays a vital role in logistics and warehousing by automating the sorting and handling of goods. These systems improve inventory management and order fulfillment processes, enhancing overall efficiency.

Matrix Design LLC provides advanced pick and place automation solutions for the logistics and warehousing industry. Our robotic pick and place systems are designed to optimize the handling and sorting of goods, improving your warehouse operations. Learn more about our logistics automation solutions on our pick and place automation page.

10. Textile and Apparel Manufacturing

In textile and apparel manufacturing, pick-and-place automation is used to handle fabrics and garments efficiently. These systems streamline the assembly and packaging of clothing items, improving production speed and accuracy.

Matrix Design LLC offers tailored pick and place automation equipment for the textile and apparel industry. Our automated pick and place systems enhance the handling and processing of textiles, contributing to a more efficient production line. For more information on how our solutions can benefit your textile manufacturing, visit our main automation page.

Conclusion

Pick-and-place automation has revolutionized various industries by enhancing efficiency, precision, and flexibility. At Matrix Design LLC, we provide advanced robotic pick and place systems that cater to the unique needs of different sectors. Our solutions, including industrial pick and place robots and Fanuc pick and place robots, are designed to optimize your manufacturing processes.

For personalized assistance with your automation needs and to explore how our solutions can benefit your operations, please fill out our contact form to connect with a Matrix automation expert. Visit our pick and place automation page to learn more about our offerings and how we can help you achieve your production goals.