Common Challenges in Assembly Automation and How to Overcome Them

Assembly automation has revolutionized manufacturing by enhancing efficiency, consistency, and scalability. However, transitioning to automated systems is not without its challenges. Understanding these common obstacles and implementing effective strategies to overcome them can ensure a smooth integration and maximize the benefits of automation. This white paper explores these challenges and offers solutions, showcasing how Matrix Design LLC’s expertise in assembly automation can assist you in overcoming them.

1. Integration with Existing Systems

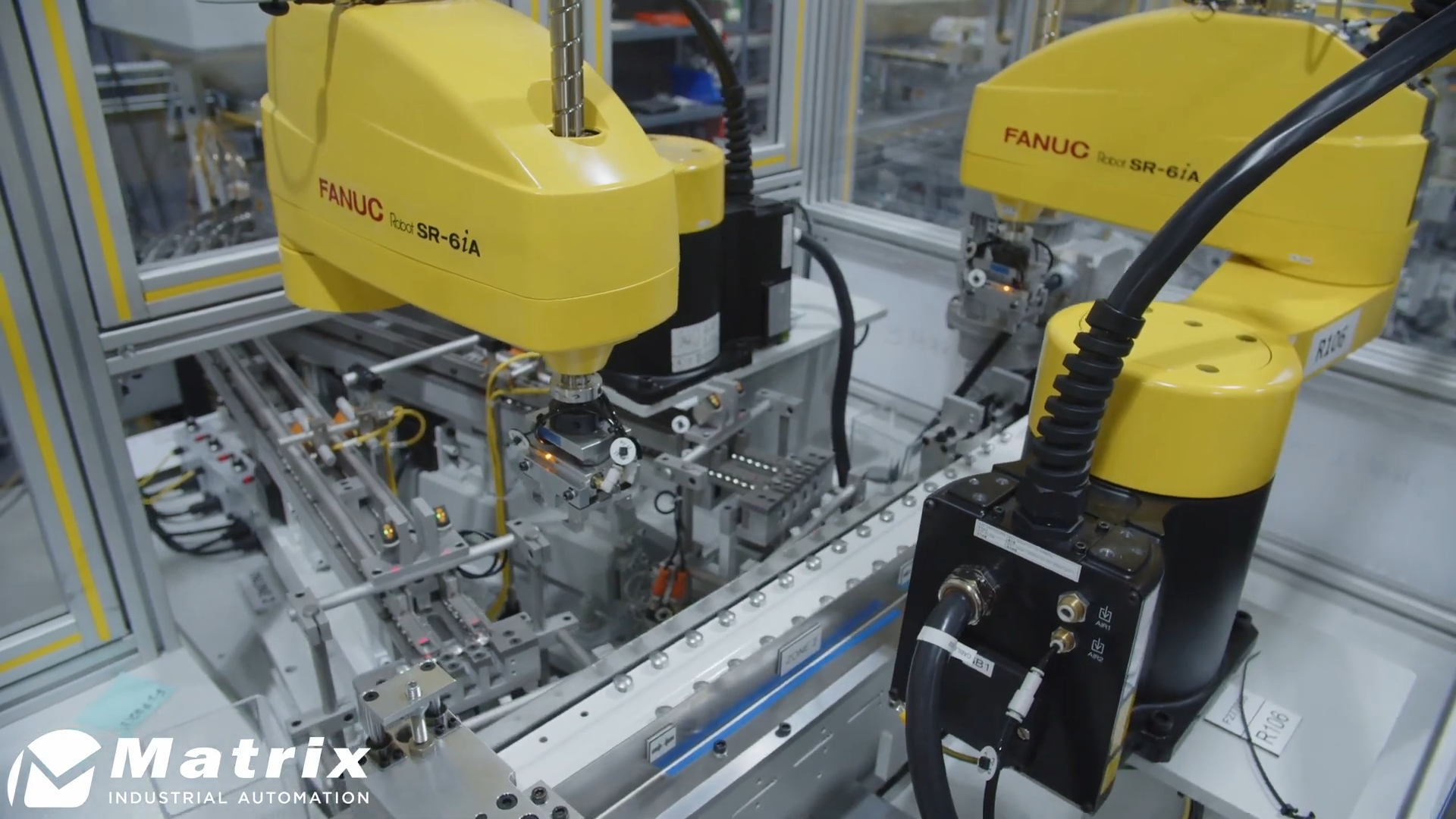

One of the primary challenges in factory assembly automation is integrating new automated systems with existing infrastructure. Compatibility issues between new robotic assembly lines and older machinery can disrupt production and lead to costly delays.

Solution: When implementing assembly line automation equipment design solutions, it’s crucial to work with a provider who understands how to seamlessly integrate new technology with your existing systems. Matrix Design LLC excels in providing custom automated assembly system builder services that ensure smooth integration. Our solutions are designed to work harmoniously with your current setup, minimizing disruptions. Learn more about our integration capabilities on our assembly automation page and consult with our experts for tailored solutions.

2. High Initial Costs

The upfront investment required for assembly line automation equipment design can be substantial. Many manufacturers are concerned about the cost of purchasing and installing advanced automation systems.

Solution: While the initial costs may be high, the long-term benefits, such as increased productivity and reduced labor costs, outweigh the investment. Matrix Design LLC offers cost-effective assembly line automation equipment design factory services that provide excellent value. Our solutions are designed to deliver a strong return on investment by enhancing your operational efficiency. To explore how our cost-effective solutions can benefit your business, visit our assembly automation page and fill out our contact form for personalized advice.

3. Complexity in System Design

Designing a custom automated assembly system involves addressing complex requirements and ensuring that the system meets specific production needs. The complexity of designing for automated assembly can be a significant hurdle.

Solution: Working with an experienced assembly line automation equipment design maker can simplify this process. Matrix Design LLC specializes in providing comprehensive assembly line automation equipment design solutions. Our expertise in designing systems tailored to your unique needs ensures that your automation setup is efficient and effective. For more information on how we can help with your system design, visit our assembly automation page and get in touch with our team.

4. Ensuring System Reliability and Maintenance

Robotic assembly lines require regular maintenance and timely repairs to ensure continuous operation. Ensuring system reliability and managing maintenance can be challenging, particularly if technical issues arise.

Solution: Partnering with a reliable provider like Matrix Design LLC can alleviate these concerns. Our assembly line automation equipment design services include ongoing support and maintenance to keep your systems running smoothly. We offer comprehensive service packages that address potential issues before they impact your operations. Learn more about our support services on our assembly automation page and reach out to us for expert assistance.

5. Training and Skill Development

Implementing robotic assembly lines often requires new skills and training for your workforce. Ensuring that your team is adequately trained to operate and maintain the new systems is essential for successful automation.

Solution: Matrix Design LLC provides training and support to help your team adapt to the new automated systems. Our custom automated assembly system builder services include comprehensive training programs that equip your staff with the knowledge and skills needed to operate and maintain the systems effectively. For details on our training programs, visit our assembly automation page and fill out our contact form to discuss your training needs.

Conclusion

While assembly automation presents several challenges, understanding these obstacles and implementing effective solutions can lead to successful integration and significant benefits. Matrix Design LLC is dedicated to helping you overcome these challenges with our expertise in assembly line automation equipment design services. To explore how we can support your automation journey, visit our assembly automation page and contact us through our contact form to speak with a Matrix automation expert today.