Ultimate Guide to Robotic Deburring

Introduction

In the fast-paced world of manufacturing, achieving precise and efficient finishing processes is crucial for maintaining high product quality and operational efficiency. Traditional methods of deburring often struggle to meet the demands of modern manufacturing due to limitations in consistency and speed. Robotic deburring emerges as a transformative solution, integrating automation and advanced technologies to revolutionize the deburring process.

What is Robotic Deburring?

Robotic deburring involves the use of automated systems equipped with robotic arms and specialized tools to remove burrs and imperfections from machined parts. This process not only enhances product quality but also ensures uniformity and repeatability in manufacturing operations. To learn more about how robotic deburring enhances product quality, visit Matrix Design LLC’s robotic deburring page.

Key Components of Robotic Deburring Systems

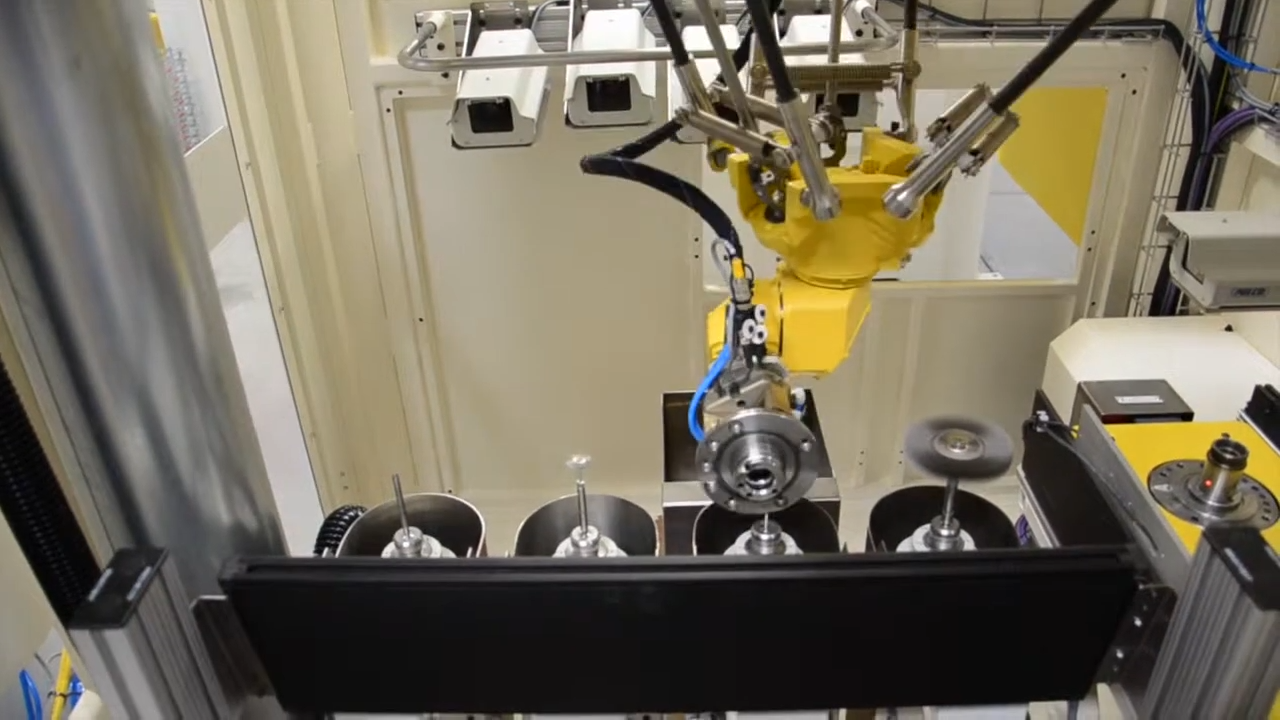

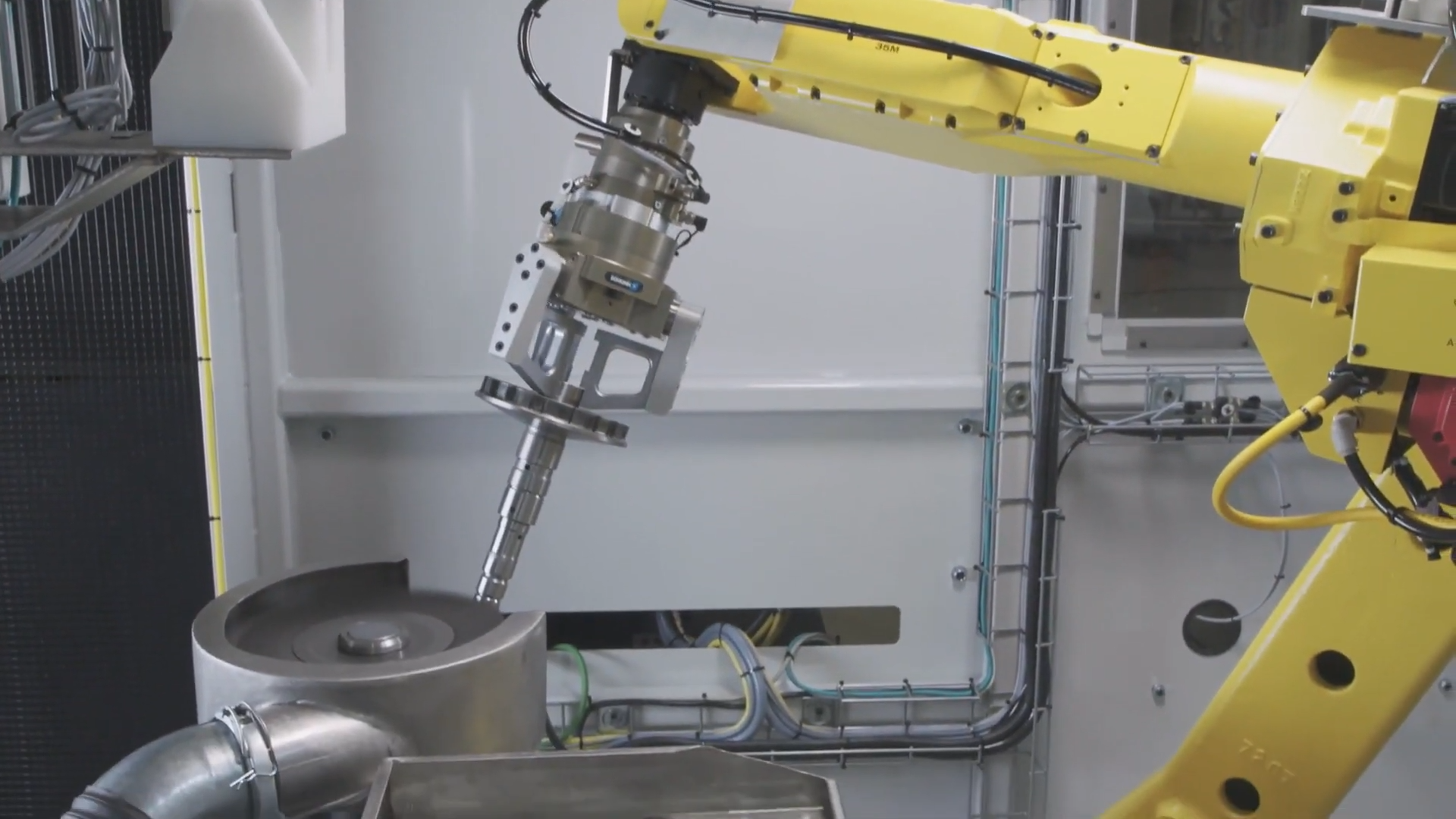

- Robotic Arms and End-Effectors

At the heart of robotic deburring systems are robotic arms equipped with versatile end-effectors such as grinding tools, abrasive wheels, or brushes. These tools are tailored to handle various materials and geometries with precision, ensuring thorough deburring without damaging the workpiece surface. For detailed insights into robotic arm technologies, visit our robotic deburring page.

- Vision Systems and Sensors

Advanced vision systems and sensors play a crucial role in robotic deburring by providing real-time feedback. This allows robots to adapt dynamically to part geometries and surface conditions, optimizing the deburring process for each specific application. Learn more about the integration of vision systems in robotic deburring on our main robotic deburring page.

- Programming and Control Software

Robotic deburring systems rely on sophisticated programming and control software to execute precise movements and adjustments. These systems enable path planning, force control, and integration with other manufacturing processes, enhancing overall efficiency and reducing cycle times. Explore the capabilities of programming software in robotic deburring on our dedicated robotic deburring page.

Benefits of Robotic Deburring

Robotic deburring offers a wide range of benefits over traditional methods:

- Consistency and Quality: Robots ensure consistent deburring results, maintaining high product quality across production batches. Discover more about how robotic systems ensure consistency on our robotic deburring page.

- Speed and Efficiency: Automated deburring processes are significantly faster than manual methods, leading to increased throughput and reduced production costs.

- Safety: By automating repetitive and hazardous tasks, robotic deburring enhances workplace safety and reduces the risk of injuries. Learn about the safety benefits of robotic deburring on our robotic deburring page.

- Flexibility: Robotic systems can handle diverse part geometries and materials, making them suitable for various industries including automotive, aerospace, electronics, and medical devices.

Applications of Robotic Deburring

Robotic deburring finds extensive application in industries where precision and efficiency are critical. From removing burrs in automotive components to ensuring smooth surfaces in aerospace parts, robotic deburring systems contribute to enhancing product performance and aesthetics. Explore specific industry applications on our robotic deburring page.

Future Trends in Robotic Deburring

Looking ahead, the field of robotic deburring is poised for continuous innovation:

- Advanced Robotics: Integration with artificial intelligence (AI) and machine learning (ML) will enable robots to optimize deburring strategies based on real-time data and predictive analytics. Visit our robotic deburring page to learn more about AI integration.

- Collaborative Robotics: Collaborative robots (cobots) will play a more significant role in deburring operations, working safely alongside human operators in shared workspaces.

- Sustainability: Robotic deburring systems contribute to sustainable manufacturing practices by reducing material waste and energy consumption. Learn more about sustainability efforts in robotic deburring on our robotic deburring page.

Conclusion

Robotic deburring technologies represent a transformative shift in manufacturing, offering unmatched precision, efficiency, and safety benefits. As industries continue to embrace automation, the role of robotic deburring will only grow, setting new standards for quality and productivity.

Learn More

For in-depth insights into robotic deburring technologies and how they can benefit your manufacturing processes, visit Matrix Design LLC’s robotic deburring page.