Top 5 Benefits of Implementing Assembly Automation in Your Manufacturing Process

In the rapidly evolving landscape of manufacturing, staying competitive means embracing innovation. One of the most impactful advancements in manufacturing technology is assembly automation. Implementing assembly automation in your production process can yield numerous benefits, from increased efficiency to enhanced product quality. This white paper explores the top five benefits of integrating assembly automation and how Matrix Design LLC can help you achieve these advantages with our cutting-edge solutions.

1. Increased Efficiency and Productivity

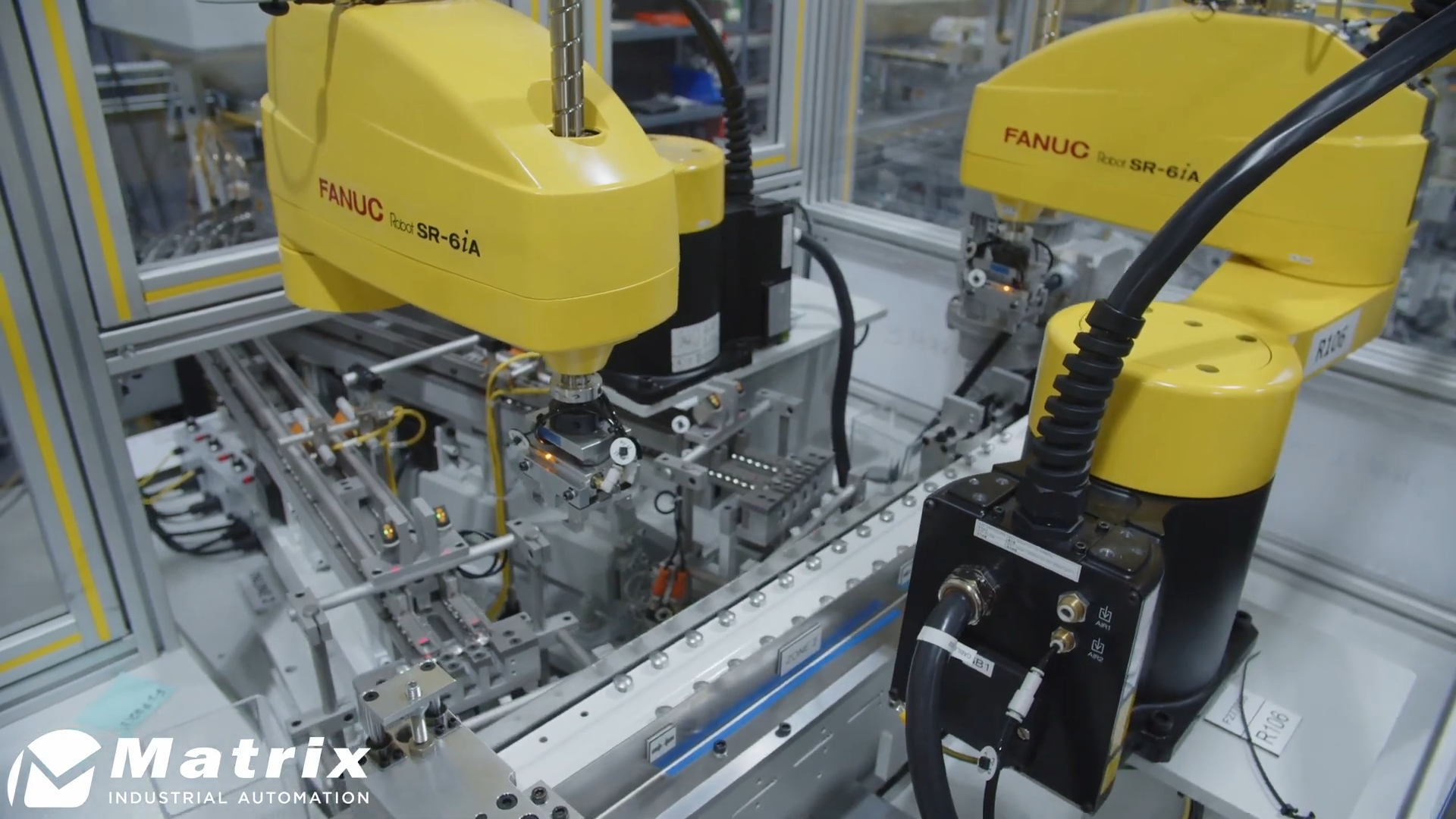

One of the primary benefits of assembly automation is the significant boost in efficiency and productivity. Robotic assembly lines are designed to operate continuously without the need for breaks, which results in higher output and faster production cycles. Automated systems streamline the assembly process by reducing manual handling, minimizing errors, and optimizing the workflow.

At Matrix Design LLC, we specialize in designing custom automated assembly systems that are tailored to your specific production needs. Our factory assembly automation solutions ensure that your production lines operate at peak efficiency, allowing you to meet growing demand with ease. Learn more about how our assembly line automation equipment design services can transform your manufacturing process by visiting our assembly automation page.

2. Improved Product Quality and Consistency

Assembly line automation equipment design services play a crucial role in enhancing product quality and consistency. Automated systems are equipped with precise sensors and controls that ensure each component is assembled accurately. This consistency reduces the likelihood of defects and variability, leading to higher-quality products.

Matrix Design LLC’s expertise in assembly line automation equipment design solutions means that we can provide you with advanced technology that ensures your products meet the highest standards. Our robotic assembly lines are engineered for precision, contributing to improved product reliability. Discover how our design for automated assembly can benefit your operations by contacting us through our contact form.

3. Cost Savings and Reduced Labor Costs

Implementing assembly automation can lead to significant cost savings by reducing the need for manual labor. While the initial investment in automation technology may seem substantial, the long-term savings on labor costs and operational expenses make it a worthwhile investment. Automated systems also help minimize material waste and energy consumption, further contributing to cost reduction.

Matrix Design LLC offers comprehensive assembly line automation equipment design factory services that provide cost-effective solutions tailored to your budget. Our custom automated assembly system builder can help you achieve substantial savings while maintaining high production standards. Learn more about how we can optimize your cost-efficiency by exploring our assembly automation solutions and reaching out to our experts.

4. Enhanced Safety and Working Conditions

Safety is a critical concern in any manufacturing environment. Automated assembly lines help mitigate safety risks by handling dangerous or repetitive tasks that could lead to workplace injuries. Robotic systems are designed to operate in hazardous conditions, protecting your workforce and improving overall working conditions.

Matrix Design LLC is committed to providing assembly line automation equipment design maker services that prioritize safety. Our systems are engineered with safety features to ensure a secure working environment while boosting productivity. To learn more about our safety-enhancing automation solutions, please visit our assembly automation page and get in touch with our team.

5. Flexibility and Scalability

Modern assembly automation systems offer unparalleled flexibility and scalability, allowing manufacturers to adapt to changing market demands and production requirements. Automated systems can be reconfigured to handle different products or adapt to new processes, providing a versatile solution for evolving manufacturing needs.

Matrix Design LLC’s custom automated assembly system builder provides scalable solutions that grow with your business. Our design for automated assembly is engineered to be adaptable, ensuring that your manufacturing process remains agile and responsive. Explore how our scalable solutions can meet your future needs by contacting us through our contact form.

Conclusion

The benefits of implementing assembly automation in your manufacturing process are clear: increased efficiency, improved quality, cost savings, enhanced safety, and flexibility. Matrix Design LLC is dedicated to helping you harness these advantages through our expert assembly line automation equipment design services. To learn more about how we can support your automation needs, visit our assembly automation page or fill out our contact form to speak with a Matrix automation expert today.